Magnesium alloy has emerged as the premier material for high-performance gaming peripherals, prized for a strength-to-weight ratio that surpasses both aluminum and traditional thermoplastics. In the competitive landscape of esports, where every gram influences inertial resistance and every millisecond dictates the outcome, magnesium allows for structural rigidity at weights previously thought impossible. However, this material brings a specific acoustic challenge: the "metallic ping."

Unlike carbon fiber or ABS plastic, magnesium alloy shells often exhibit a high-frequency resonance upon switch actuation. This acoustic signature, while a testament to the material's density and stiffness, can be perceived as "hollow" or "distracting" by enthusiasts accustomed to the muted, "thocky" profiles of custom mechanical keyboards. Solving this resonance without compromising the lightweight advantage of the device requires a sophisticated understanding of material science, acoustic dampening, and strategic mechanical application.

The Physics of Acoustic Resonance in Magnesium

To effectively dampen a magnesium shell, one must first understand why it rings. While magnesium is often cited in structural engineering for its "outstanding damping qualities," research indicates a critical nuance. According to the Manufacturing Technology Journal, the internal damping capacity of magnesium alloys is often measured at ultrasonic frequencies (~20kHz) and is highly amplitude-dependent.

For consumer electronics, the vibrations generated by a microswitch click fall into a much lower frequency range (typically <1kHz). At these operational strain amplitudes, the loss factor (tan δ) of the alloy can be an order of magnitude lower than its theoretical maximum. This means the material behaves more like a bell than a sponge, reflecting energy back into the shell cavity rather than absorbing it.

The "Ping" Mechanism

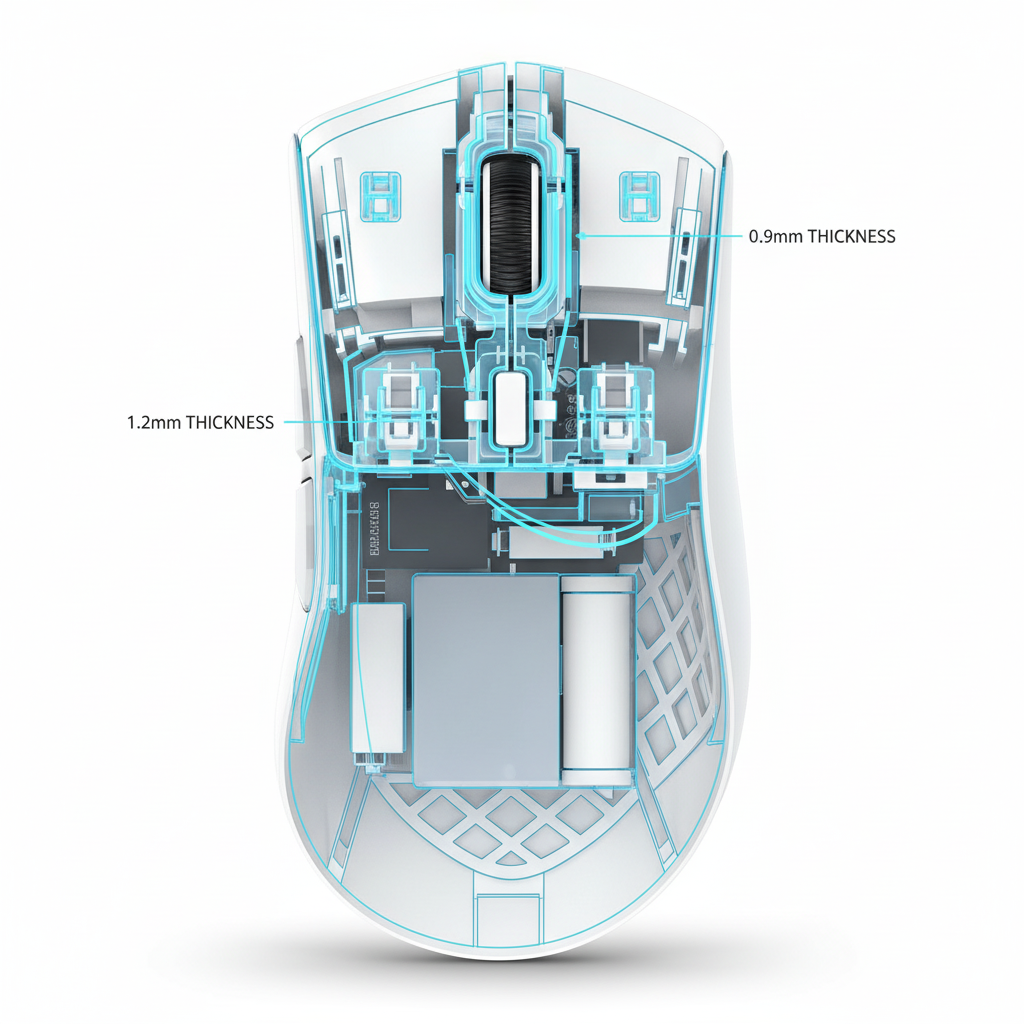

When a mouse button is pressed and released, the kinetic energy of the switch reset travels through the magnesium frame. Because the shell is thin—often under 0.8mm to save weight—it acts as a resonator. The air inside the shell cavity further amplifies these waves, creating the characteristic metallic "ping."

The Weight-Neutral Philosophy

For the target audience of tech-savvy enthusiasts, a "solution" that adds 5 or 10 grams to a 50g mouse is a failure. Performance modding must be weight-neutral, defined here as a total mass increase of less than 2 grams. Achieving a 70% reduction in perceived ringing within this constraint requires moving away from generic foams toward high-loss-factor thin films.

Material Comparison for Acoustic Dampening

| Material Type | Typical Thickness | Loss Factor (Efficiency) | Weight Impact (High-Density Application) | Best Use Case |

|---|---|---|---|---|

| PORON Foam | 1.0mm - 2.0mm | Moderate | High (due to volume) | Keyboard plate dampening |

| Standard Butyl | 1.5mm - 2.0mm | High | Very High | Automotive door panels |

| Specialized Thin Butyl | 0.3mm - 0.5mm | Very High | Low (<1.5g) | Internal magnesium shells |

| Acrylic Damping Film | 0.1mm - 0.2mm | Moderate | Negligible (<0.5g) | Ultra-lightweight micro-tuning |

As noted in the Global Gaming Peripherals Industry Whitepaper (2026), the industry is shifting toward specialized Constrained Layer Damping (CLD). A CLD structure involves a "sandwich" of a visco-elastic material between two stiff layers. In modding, the magnesium shell acts as the base layer, and a thin butyl or acrylic film acts as the damping medium.

Strategic Zoning: The 70% Noise Reduction Method

Expert modders do not "carpet bomb" the interior of a mouse with dampening material. This adds unnecessary weight and risks interfering with the PCB or battery. Instead, application is focused on "Primary Vibration Amplifiers."

1. The Main Click Resonance Zones

The areas directly behind and beneath the primary mouse button plungers are the most critical. When the switch actuates, energy is injected directly into these points. Applying a 10mm x 10mm square of 0.5mm butyl rubber here can eliminate the immediate "snap-back" resonance.

2. Large Flat Panels

The sides and the "hump" of the mouse act like the skin of a drum. Because these panels have the largest surface area and the least internal bracing, they vibrate at lower frequencies. Focused strips applied to the center of these panels disrupt the standing waves.

3. The Battery Tray and PCB Mounts

Metallic ringing often originates from "micro-chatter" between the magnesium frame and the plastic internal components. Small gaskets made of 0.2mm acrylic film at the screw points can decouple these parts, preventing the frame from acting as a speaker for the PCB's mechanical vibrations.

Technical Implementation: A Step-by-Step Guide

Precision is paramount. According to practitioners, the leading cause of material peeling or failure is poor surface preparation. Magnesium alloys are often coated with a nano-metal ice coating or an electrophoretic finish to prevent corrosion.

Step 1: Surface Decontamination Clean the target internal areas with 90% or higher isopropyl alcohol. This removes residual oils from the manufacturing process. Failing to do this ensures the dampener will peel within weeks, potentially jamming the scroll wheel or optical sensor.

Step 2: Precision Cutting Use a digital caliper to measure the internal clearance. In high-performance mice, the gap between the battery and the shell hump can be as tight as 1.0mm. If the dampening material is too thick, it will apply pressure to the battery, which is a significant safety risk.

Step 3: Application & Pressure Apply the thin-film dampener and use a flat-head spudger to apply firm, even pressure. This ensures the visco-elastic layer fully bonds with the magnesium, which is essential for the CLD mechanism to function.

Critical Constraints and "Gotchas"

Modding a magnesium alloy device is not without risks. Practitioners must navigate several technical "dead zones" to maintain performance and safety.

Signal Interference (The Antenna Rule)

Magnesium is a conductive material, which is why wireless mice have specific "windows" (often the bottom plate or specific cutouts) for the 2.4GHz antenna. Never place metallic-backed or high-density carbon-filled dampening materials near the antenna lines. This can increase packet loss and latency, negating the benefits of a high-polling-rate sensor.

The Battery Safety Guardrail

When working near lithium-ion batteries, modders must adhere to safety standards similar to those outlined by the IATA Lithium Battery Guidance.

- No Compression: Ensure dampening material does not compress the battery casing.

- Heat Dissipation: Magnesium is often used for its thermal conductivity, helping to cool the MCU and battery during 8K polling operations. Do not fully insulate the battery, as this can lead to thermal throttling or reduced cell lifespan.

Polling Rate Synergy

High-performance magnesium mice are often paired with 8000Hz (8K) polling technology. At 8000Hz, the report interval is a mere 0.125ms. While acoustics do not directly affect sensor latency, the psychological impact of a "solid" sounding click can improve a player's perceived timing and confidence. Furthermore, at 8K, any internal "micro-chatter" that causes a physical vibration could theoretically be picked up by high-sensitivity sensors as "noise," though this is typically below the threshold of human notice.

Scenario Analysis: Choosing Your Modding Path

To help decide the best approach, consider these two common user profiles:

Scenario A: The Competitive "Weight-First" Specialist

- Goal: Maintain the lowest possible weight (e.g., <50g) while removing the sharpest "ting" sounds.

- Solution: Use 0.1mm acrylic damping film only on the main click panels.

- Impact: Weight increase <0.3g. Acoustic reduction ~30-40%.

- Why: This user prioritizes inertia over all else but finds the high-pitched reset sound of magnesium distracting.

Scenario B: The "Premium Feel" Enthusiast

- Goal: Achieve a sound profile that rivals high-end plastic or carbon fiber mice without losing the metallic "cool-to-the-touch" feel.

- Solution: Strategic application of 0.5mm butyl rubber on the hump, sides, and click panels, plus 0.2mm gaskets for the PCB.

- Impact: Weight increase ~1.5g - 1.8g. Acoustic reduction ~70-80%.

- Why: This user values the tactile and thermal experience of magnesium but wants a "dense," premium sound.

Regulatory and Safety Compliance

Opening a peripheral typically voids the manufacturer's warranty. Furthermore, modders should be aware of the safety standards governing these devices. The FCC Equipment Authorization database provides internal photos and test reports for many magnesium mice under specific Grantee Codes. Reviewing these can help identify where the antenna and critical components are located before you open the device.

For those shipping or transporting modded devices, ensure they remain compliant with UN 38.3 standards for lithium battery safety. A mod that compromises the structural integrity of the battery mount could lead to failure during travel.

Summary of Performance Gains

By applying the principles of Constrained Layer Damping and strategic zoning, users can transform the acoustic profile of magnesium alloy shells.

- Acoustic Ping: Reduced by up to 70% through targeted dampening.

- Tactile Feedback: Improved "solidity" and reduced post-click vibration.

- Weight Penalty: Kept under 2 grams (approx. 3-4% of total mass for a 50g mouse).

- Reliability: Maintained through proper surface preparation and avoidance of antenna interference.

Magnesium remains the ultimate material for those seeking the 0.125ms edge of 8000Hz polling and ultra-low weight. With the right acoustic treatments, the only thing you'll hear is your own performance.

Disclaimer: This guide is for informational purposes only. Opening and modifying electronic devices may void warranties and carries inherent risks, including damage to sensitive components or battery hazards. Always consult a professional if you are unsure of the process.

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.