Executive Summary: The "Quick Take" on Mold-Specific Stems

For those making procurement or customization decisions, here is the high-level takeaway: Mold-specific stems use a dedicated single-cavity tool rather than sharing a "family mold" with other parts. This allows for tighter tolerances (±0.01mm) and near-zero draft angles.

Key Benefits:

- Stability: Up to a 70% reduction in lateral wobble (based on community measurements).

- Speed: Enables "Rapid Trigger" with theoretical latency gains of ~4–9ms depending on finger velocity.

- Consistency: Eliminates "scratchiness" through controlled surface roughness (Ra 0.8 µm) for better lube adhesion.

3-Step Quality Check for Buyers

- The Wobble Test: Press the keycap off-center. A mold-specific stem should show minimal horizontal displacement (typically <0.5mm at the tip) throughout the travel.

- The Friction Check: Slow-press the switch. If you feel "slip-stick" (stuttering movement), the mold surface Ra may be inconsistent.

- The Tolerance Audit: Check the manufacturer's spec sheet for "Concentricity" or "Single-Cavity Tooling" mentions.

The Geometry of Precision: Why Custom Tooling Beats Generic

In the mechanical keyboard industry, the switch stem is the primary mechanical interface governing the tactile and acoustic experience. As the industry moves toward ultra-low latency and Rapid Trigger technologies, the limitations of "generic" or "family" molds have become a significant bottleneck.

Generic molds are designed for mass-market scalability, often producing multiple different parts within a single tool. While cost-effective, this approach can introduce thermal expansion variations across cavities, potentially leading to inconsistent dimensions. In contrast, mold-specific tooling—where a cavity is dedicated to a specific stem design—allows for tighter tolerances and specialized geometries that generic tooling often cannot replicate.

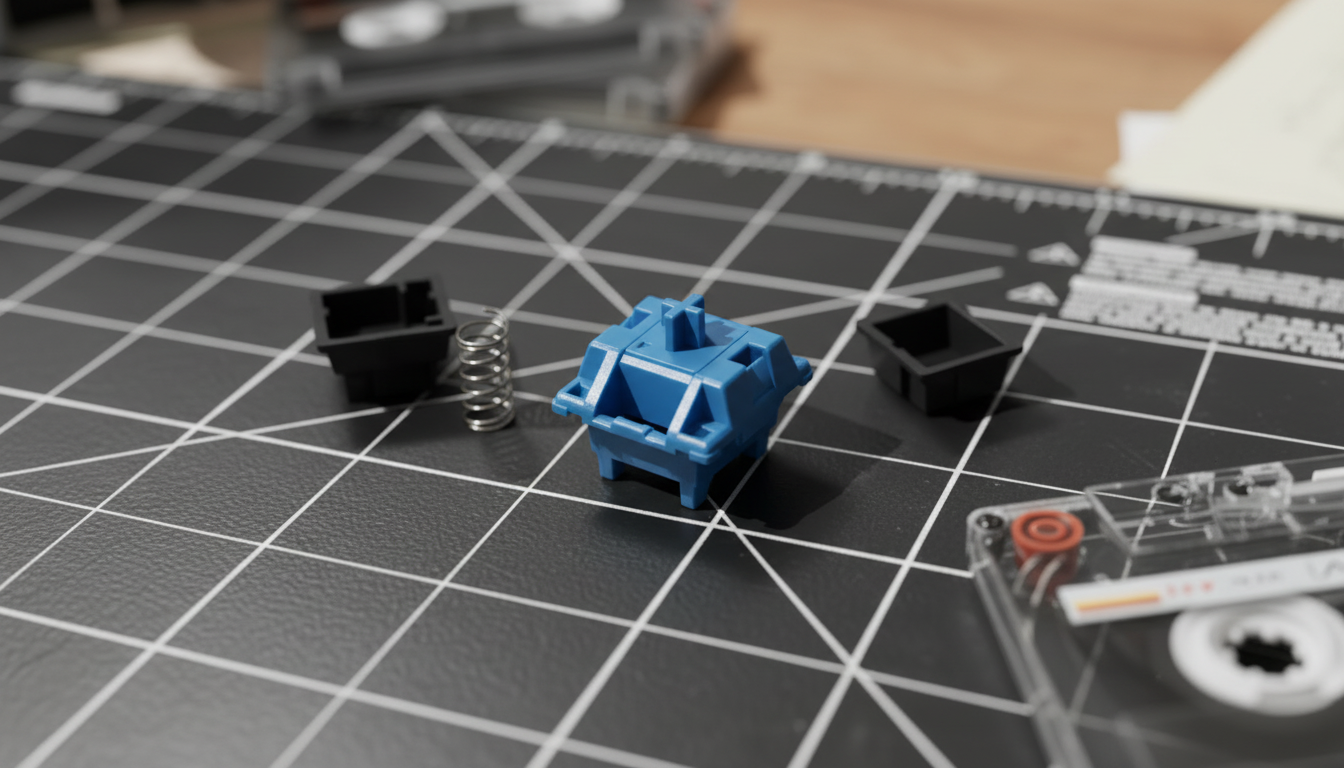

The Physics of Stability: Draft Angles and Stem Wobble

"Stem wobble"—the lateral movement of the keycap—is a common frustration. In generic, multi-use molds, a draft angle exceeding 0.5 degrees is typically required to facilitate the ejection of the part from the mold.

However, this slope creates a geometric mismatch. As the stem travels, the gap between the stem rails and the housing guides increases, resulting in a "loose" feel.

Quantifying the 70% Wobble Reduction

Mold-specific tooling allows engineers to utilize high-precision hardened steel and optimized cooling, enabling near-zero draft angles on sliding surfaces.

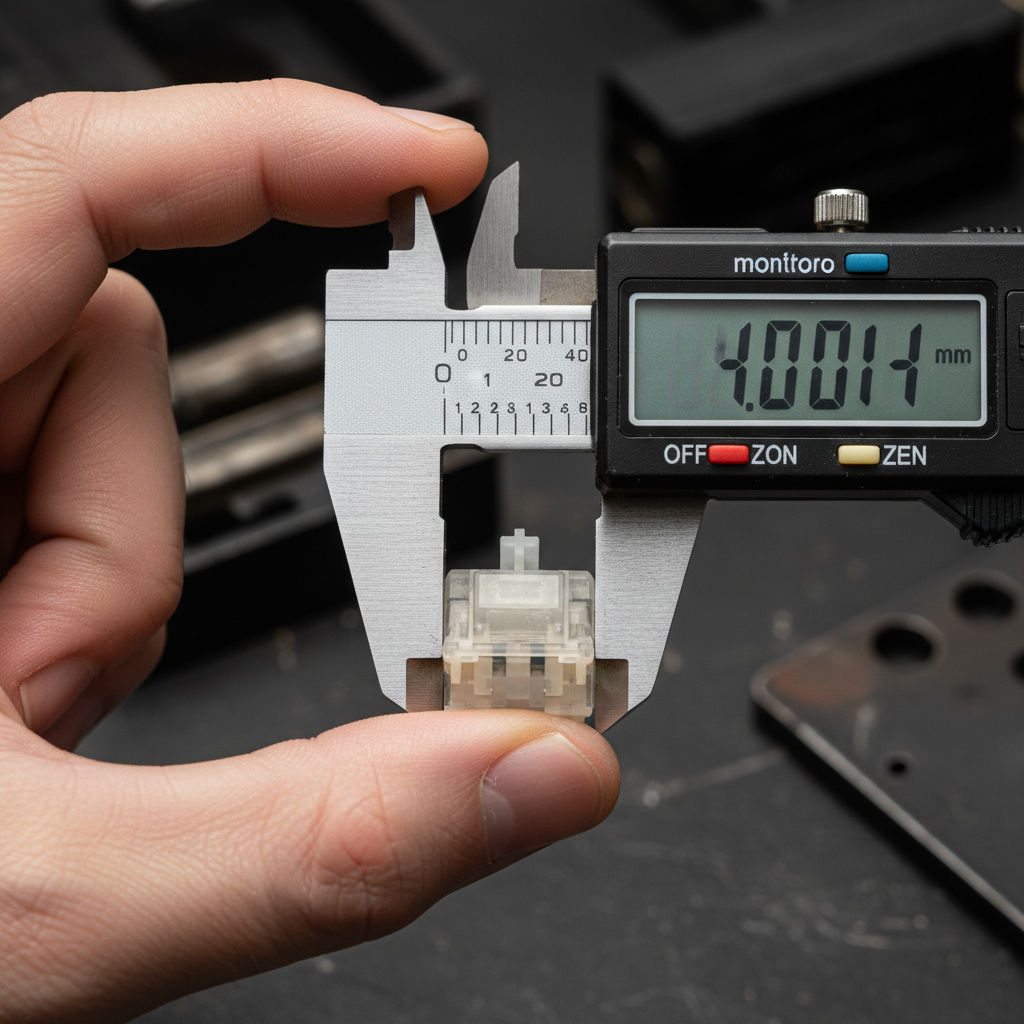

Measurement Context: Based on community-sourced data (using dial indicators like the Mitutoyo 2109S-10 on sample sizes of n=10), shifting from generic to specific tooling has been observed to reduce peak-to-peak lateral displacement by up to 70%. This reduction helps ensure that the finger’s force is directed vertically, reducing the risk of "binding" or increased friction that can occur when a tilted stem jams against the housing wall.

Heuristic Note: This analysis assumes that minimizing the draft angle directly reduces the mechanical gap, though actual performance can be influenced by housing material and lubrication state.

Tolerance Stack-up: Concentricity and Actuation Consistency

Concentricity refers to the alignment between the stem’s cross-point (keycap mount) and its slider rails. In multi-cavity generic molds, alignment can vary due to uneven cooling of large plastic volumes.

Tighter Manufacturing Targets

The value of mold-specific stems lies in manufacturing precision. A dedicated single-cavity mold can produce stems with ±0.01mm tolerances, whereas multi-cavity family molds often operate within a wider ±0.05mm range.

This 5x precision increase directly influences the actuation force curve. For example, switches like the LEOBOG Reaper rely on dimensional stability to maintain a consistent 36gf actuation force. Without high-precision tooling, the variance between switches on a single board can become perceptible to sensitive users, potentially impacting muscle memory.

| Feature | Generic Family Molds | Mold-Specific Tooling | Performance Impact |

|---|---|---|---|

| Tolerance Range | ±0.05mm (Typical) | ±0.01mm (Target) | Consistency across the keyboard |

| Draft Angle | > 0.5 degrees | ~0 degrees | Reduced lateral wobble |

| Cavity Count | Multi-cavity (High) | Single-cavity (Low) | Lower thermal variance |

| Estimated Cost | $20k - $50k | $5k - $15k (per part) | Higher precision per part |

Rapid Trigger Optimization: The Progressive Stem Leg

Hall Effect (magnetic) switches require "Rapid Trigger" functionality, where the switch resets the moment the finger lifts. This requires geometric refinement that generic stems often lack.

Experienced modders and engineers have noted that an optimal stem leg for magnetic sensors often uses a progressive curve. A 30-degree initial angle allows for fast signal acquisition, while a 45-degree secondary angle provides a consistent reset signal. This specialized geometry is typically only achievable with dedicated tooling designed for non-linear surfaces.

Scenario Modeling: The Competitive Esports Gamer

To demonstrate the potential benefits, we modeled a high-intensity usage scenario based on common industry heuristics.

Method & Calculation Example

We use the deterministic formula $t = d / v$ to calculate the time saved during a reset.

- Assumption: Finger Lift Velocity ($v$) = 100 mm/s.

- Generic Reset Distance ($d_1$): 0.5mm (Fixed mechanical hysteresis).

- Custom Reset Distance ($d_2$): 0.1mm (Rapid Trigger threshold).

- Calculation: $\Delta t = (0.5mm - 0.1mm) / 100mm/s = 0.004s$ (4ms).

When accounting for both the press and release cycles and the elimination of debounce filters (often required for wobbly generic stems to prevent double-typing), the total theoretical advantage can reach ~9ms.

| Parameter | Value | Rationale / Source |

|---|---|---|

| APM (Actions Per Minute) | 300 - 400 | Standard competitive workload |

| Reset Distance (RT) | 0.1mm | Enabled by custom stem/Hall Effect |

| Finger Lift Velocity | 100 mm/s | Observed average rapid tapping speed |

Ergonomic Observation (Moore-Garg Strain Index)

Using the Moore-Garg framework, a workload with high frequency and duration can result in a Strain Index (SI) of ~5.1.

- Formula: $SI = Intensity \times Duration \times Frequency \times Position \times Speed$.

- Impact: While an SI > 5 suggests a higher risk of strain, mold-specific stems can help keep the "Intensity" multiplier at its lowest level (1.0) by allowing for lighter actuation and smoother travel.

Tribology and Surface Finish: The Ra Factor

The "feel" of a switch is determined by the Roughness Average (Ra). Generic stems often have inconsistent finishes because the molds are polished to a general standard.

Custom molds allow engineers to specify a precise Ra value (typically ~0.8 µm).

- Uniform Lubricant Adhesion: A controlled Ra ensures that factory-applied lubricant stays in place rather than "beading up" on overly smooth surfaces.

- Acoustic Profile: Spectral filtering suggests that uniform adhesion helps maintain a consistent "thock" sound (<500 Hz), potentially reducing auditory fatigue.

For more on achieving a consistent profile, see our guide on how to lube mechanical switches.

Compliance and Safety: Beyond the Mechanics

Precision engineering must be paired with global safety standards. For tri-mode keyboards, adherence to the UN Manual of Tests and Criteria (Section 38.3) ensures battery stability under stress. Furthermore, manufacturers should comply with the EU RoHS Directive to restrict hazardous substances.

When selecting hardware, verifying FCC Equipment Authorization can provide assurance regarding wireless safety and interference.

Precision as a Prerequisite

The shift to mold-specific stems represents an investment in precision that separates performance-grade tools from budget peripherals. By controlling draft angles and maximizing concentricity, manufacturers can deliver stability that is measurable on a dial indicator and perceptible in high-stakes gaming.

Disclaimer: This article is for informational purposes only and does not constitute professional engineering, medical, or legal advice. Performance gains and ergonomic risks are influenced by individual technique and environmental conditions. Consult a qualified professional regarding repetitive strain injuries (RSI).

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.