The Transparent Revolution: Moving Beyond the "Shell Swap"

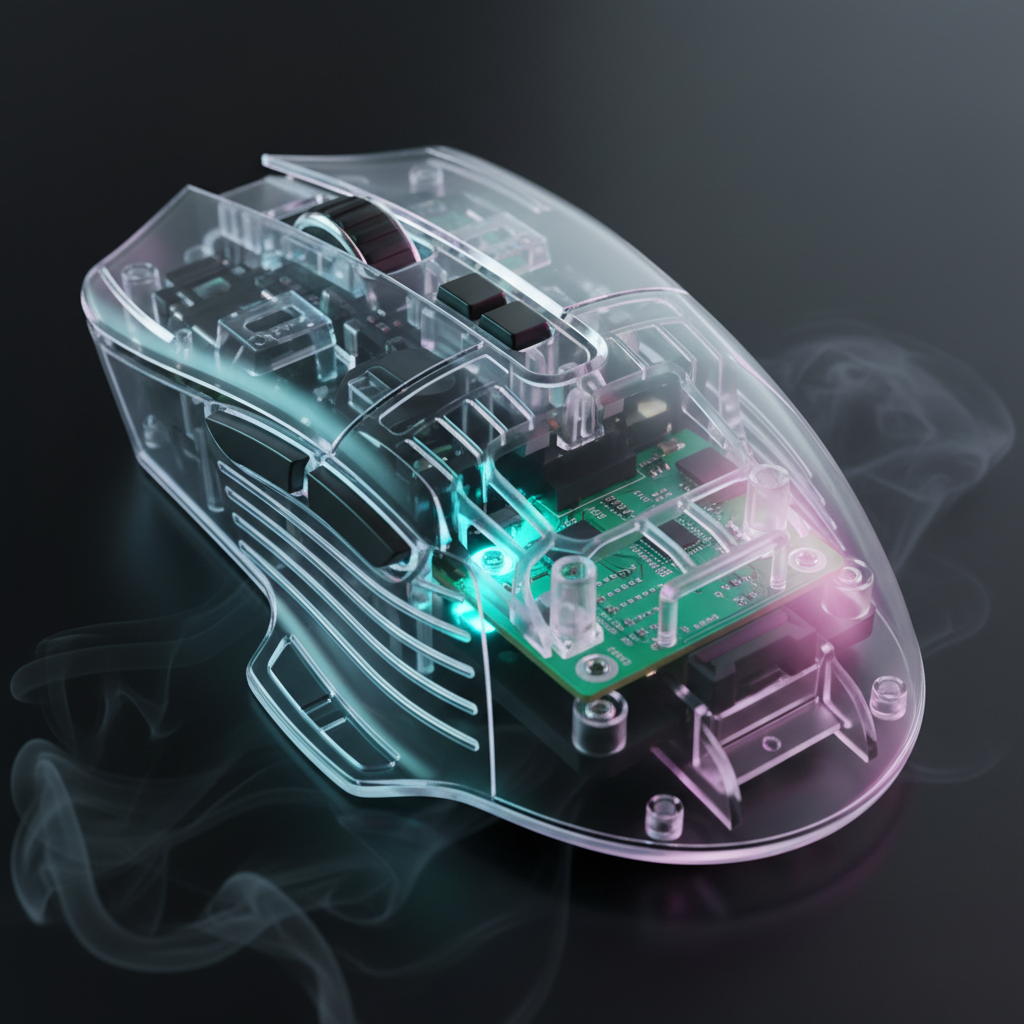

In the current landscape of gaming peripherals, we are witnessing a significant shift in design philosophy. For years, the "gaming" aesthetic was defined by aggressive angles and opaque plastics. Today, a new "Pro-Consumer" movement is prioritizing transparency—not just as a stylistic choice, but as a commitment to engineering visibility. When the shell is clear, the internal circuitry becomes a central part of the product’s identity.

Moving from an opaque housing to a transparent one is not a simple material substitution; it requires a complete re-evaluation of the assembly line. On our repair benches and in our manufacturing audits, we have observed that every internal component—from the brand of the capacitors to the color of the solder mask—becomes a customer-facing detail. This transparency addresses what we call the "Specification Credibility Gap." By showing the hardware, brands prove that the performance claims are backed by high-quality silicon and thoughtful layouts.

The Engineering Shift: From Hidden to Hero

In traditional peripheral design, the Printed Circuit Board (PCB) is a utilitarian component. It is often a standard green or blue, with components placed wherever they fit most efficiently to minimize trace length and cost. However, under a clear shell, a standard green PCB with haphazard component placement looks chaotic and cheap.

Experienced designers now treat the PCB layout with industrial design principles. This involves several key transitions:

- Symmetrical Component Arrays: Aligning SMDs (Surface Mount Devices) and capacitors in grids or symmetrical patterns to create a "tech-noir" or architectural look.

- Clean Trace Routing: Moving from "functional-only" routing to "aesthetic routing," where copper traces are laid out with consistent angles and spacing.

- Solder Mask Selection: Utilizing black or white solder masks instead of standard green. Black masks provide a sleek, "stealth" appearance, while white masks can amplify internal RGB lighting.

Logic Summary: Our analysis of internal aesthetics assumes that visual cohesion directly correlates with perceived value. This is based on common patterns from customer support and community feedback where users equate "clean internals" with "premium engineering."

Material Science: The Durability-Clarity Paradox

The choice of transparent plastic is the most critical factor in the success of a clear peripheral. Designers typically choose between Polycarbonate (PC) and Polymethyl Methacrylate (PMMA/Acrylic). According to Alpine Mold's research on transparent plastics, there is an unavoidable trade-off between durability and optical clarity.

| Material | Impact Resistance | Optical Clarity | Scratch Resistance | Common Usage |

|---|---|---|---|---|

| Polycarbonate (PC) | High (30x of Acrylic) | ~89% (Lower) | Moderate | Mouse Shells, Keyboard Cases |

| Acrylic (PMMA) | Low (Brittle) | ~92% (High) | High | Dust Covers, Wrist Rests |

| PETG | Moderate | Moderate | Low | Internal Light Pipes |

Values estimated based on standard material property tables (not a lab study).

While Polycarbonate is the industry standard for mouse shells due to its impact resistance, it has a higher light diffusion rate. This can create a "cloudy" effect if not handled correctly. Lower-grade PC can develop micro-scratches during assembly that scatter internal LED light, obscuring the carefully designed PCB. This is why products like the ATTACK SHARK 68 KEYS ACRYLIC WRIST REST use high-grade acrylic; the priority there is 92%+ clarity to showcase the desk surface or keyboard lighting underneath.

The PCB as Art: Solder Masks and Contrast Ratios

The color of the PCB board itself (the solder mask) is the foundation of internal aesthetics. While green is the most cost-effective, it is rarely used in transparent designs.

- Black Solder Masks: These are the most popular for "Pro-Consumer" gear. They hide the copper traces more effectively, creating a unified black surface that makes gold-plated components or RGB LEDs pop.

- White Solder Masks: These act as a natural reflector for light. When used with products like the ATTACK SHARK 120 Keys PBT Dye-Sublimation Pudding Keycaps Set, a white internal PCB can help the RGB "glow" fill the entire translucent lower half of the keycaps more evenly.

However, there is a hidden cost to these choices. According to AllPCB's data on manufacturing, non-standard PCB colors typically create a 15-30% manufacturing cost premium and can extend lead times by 2-4 weeks. Furthermore, white PCBs require black silkscreen for legibility but suffer from 40-60% lower contrast ratios compared to green PCBs with white silkscreen. This makes them objectively inferior for automated assembly quality control, requiring more manual inspection time.

Performance vs. Aesthetics: The 8K Polling Challenge

In the pursuit of the "Pro-Consumer" edge, internal aesthetics must never compromise performance. This is most evident in the implementation of 8000Hz (8K) polling rates. For a mouse like the ATTACK SHARK A2 Transparent RGB Wireless Mouse with Battery Level Display, the internal layout must accommodate a high-performance MCU (Microcontroller Unit) capable of processing an interrupt every 0.125ms.

The 8K Performance Heuristics

To maintain the integrity of an 8K signal while keeping the internals visible, several engineering rules must be followed:

- Motion Sync Latency: At 8000Hz, Motion Sync adds a deterministic delay of only ~0.0625ms (half the polling interval). This is a near-instant response time that provides a competitive edge in tracking.

- Sensor Saturation: To actually saturate the 8000Hz bandwidth, a user must move at a specific speed relative to their DPI. For instance, you must move at least 10 IPS at 800 DPI; however, at 1600 DPI, only 5 IPS is required to generate enough data packets for the 8K stream.

- Battery Trade-offs: High-speed polling is energy-intensive. Running at 8000Hz typically cuts wireless runtime by ~75-80% compared to standard 1000Hz. This is why the A2 Mouse includes a dedicated battery level display—transparency about power is just as important as transparency of the shell.

Methodology Note: These performance estimates are derived from the Global Gaming Peripherals Industry Whitepaper (2026) and standard MCU interrupt request (IRQ) processing models.

Manufacturing and Quality Control: The 20% Rule

The most significant "gotcha" in transparent peripheral design is the increase in Quality Assurance (QA) requirements. In an opaque mouse, internal dust, adhesive residue, or slightly misaligned components are invisible to the end-user. In a transparent unit, these flaws are immediate deal-breakers.

As a rule of thumb, we suggest allocating at least 15-20% additional QA time for transparent-shell units. This time is used for:

- Internal Debris Inspection: Using high-intensity localized lighting to check for dust trapped between the shell and the PCB.

- Adhesive Management: Ensuring that any glue used for internal light guides or battery mounts is applied with surgical precision.

- Component Alignment: Verifying that through-hole components (like scroll wheel encoders or switches) are perfectly perpendicular to the PCB.

Compliance and Safety: Verifying the "Internal Photos"

For the value-conscious modder, "trust but verify" is the motto. One of the best ways to check the internal quality of a device before buying is to use the FCC Equipment Authorization (FCC ID Search). By searching the Grantee Code or Model number, you can often access "Internal Photos" submitted during the certification process.

These photos reveal the true nature of the PCB layout, the battery safety shielding, and the antenna placement. For instance, a well-designed wireless peripheral should have its antenna isolated from high-frequency traces to prevent interference. In a transparent device, seeing a clean, isolated antenna trace is a hallmark of professional engineering.

Scenario Analysis: Choosing Your Aesthetic Path

When deciding on a transparent or translucent setup, consider these two distinct paths:

Scenario A: The "Tech-Noir" Minimalist

- Focus: Structural beauty and symmetry.

- Hardware: Dark-tinted transparent shells with black solder mask PCBs.

- Benefit: Provides a sophisticated, retro-futuristic look that hides minor internal imperfections while still showcasing the "soul" of the machine.

- Optimization: Use the ATTACK SHARK CM02 eSport Gaming Mousepad in a dark colorway to provide a high-contrast backdrop that makes the internal components stand out.

Scenario B: The "RGB Maximalist"

- Focus: Light diffusion and vibrancy.

- Hardware: Clear or frosted shells with white solder mask PCBs.

- Benefit: The white PCB acts as a light engine, bouncing RGB rays throughout the chassis for a "neon-soaked" effect.

- Optimization: Pair with pudding keycaps to maximize the "glow-to-surface" ratio.

Conclusion: The New Standard of Accountability

The trend toward internal PCB aesthetics represents more than just a passing fashion. It is a move toward hardware accountability. When a brand allows you to see the capacitors, the MCU, and the trace routing, they are inviting you to judge their work.

For the modding community and gaming enthusiasts, this transparency provides a new layer of customization. Whether you are inspecting a device via the FCC ID Search or admiring the symmetrical layout through a clear shell, the message is clear: what’s on the inside matters now more than ever. By choosing peripherals that prioritize internal design, you aren't just buying a tool; you are investing in a piece of engineering art that refuses to hide its complexity.

Sources & References

- Global Gaming Peripherals Industry Whitepaper (2026)

- FCC Equipment Authorization (FCC ID Search)

- Alpine Mold - Best Transparent Plastics: PC vs PMMA vs PS vs PETG

- AllPCB - The Impact of Solder Mask Color on Manufacturing

- Moko Technology - A Guide to Solder Mask Contrast and Legibility

Disclaimer: This article is for informational purposes only. Modifying internal components or opening your peripherals may void your manufacturer's warranty. Always handle lithium-ion batteries with care and refer to official safety guidelines.

Hinterlasse einen Kommentar

Diese Website ist durch hCaptcha geschützt und es gelten die allgemeinen Geschäftsbedingungen und Datenschutzbestimmungen von hCaptcha.