The Technical Reality of Tooling Fatigue in Gaming Peripherals

Quick Verdict: You should consider immediate shell maintenance or a hardware upgrade if you identify structural "creaking" under standard grip pressure or visible "flash lines" (seam ridges) exceeding 0.1mm. These symptoms are primary indicators of tooling fatigue, a manufacturing drift that can increase ergonomic strain and degrade competitive consistency. Use the diagnostic checklist below to evaluate your current gear.

Quick Diagnosis Checklist

- Acoustic: High-pitched creaking when applying lateral pressure.

- Visual: Seam lines feel sharp or visible ridges exceed 0.1mm.

- Tactile: Texture feels "mushy" or slippery despite cleaning.

- Performance: Side buttons require more travel or force to actuate than when new.

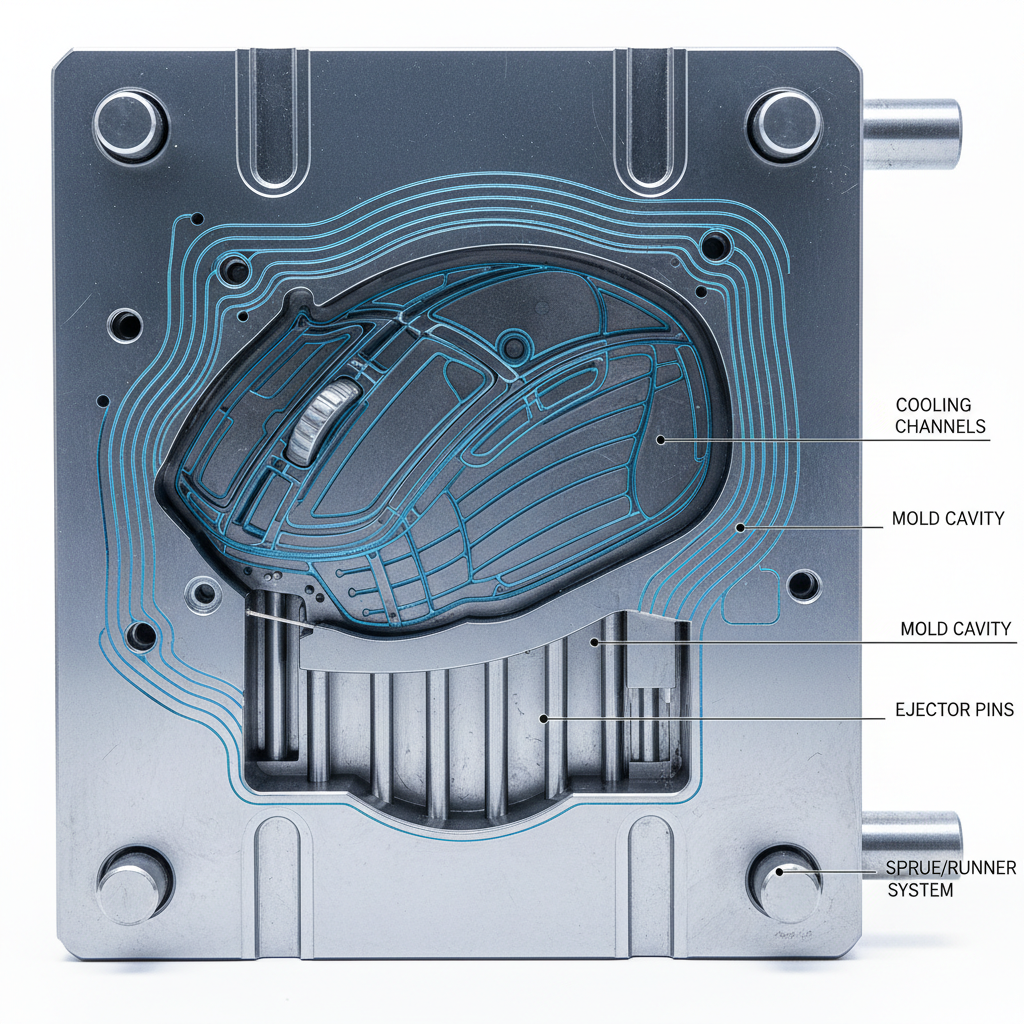

In the high-stakes world of competitive gaming, hardware performance is often measured by sensor accuracy and switch actuation. However, the structural integrity of the peripheral—the shell—remains a significant component of the performance equation. Every plastic housing begins its life as molten polymer injected into a precision-machined steel mold. Over thousands of production cycles, these molds undergo physical degradation known as tooling fatigue.

Identifying when a shell has reached the end of its functional lifecycle is important for maintaining ergonomic consistency and structural reliability. While many users attribute a "creaky" mouse or a "loose" keyboard frame to simple wear and tear, these symptoms often point to manufacturing drift. Understanding the mechanisms of injection molding allows performance-savvy gamers to make informed decisions about hardware upgrades.

The Physics of Injection Molding and Material Durability

The manufacturing of gaming shells involves high-pressure injection molding. According to Integrated Solutions (Manufacturing Industry Guide), the selection of materials such as ABS (Acrylonitrile Butadiene Styrene), Polycarbonate, and Nylon is foundational to product longevity. These materials offer specific tensile strength and impact resistance, but their precision is limited by the mold that shapes them.

As molten plastic is forced into the mold cavity, the steel surfaces experience thermal stress and mechanical abrasion. Over time, the sharp edges of the mold can round, and the clamping force required to keep the two halves together may cause subtle warping. This leads to a deviation in plastic part tolerances (Industry Standard), which must be maintained to ensure that internal components like PCBs and side-button assemblies fit correctly.

The Mechanism of Tooling Drift

Tooling drift occurs when the physical dimensions of the mold change due to repeated use. This is a gradual erosion of precision. In premium manufacturing, AI-driven quality inspection is often employed to detect these defects early. As noted by IPQC (Quality Control Blog), AI minimizes the time required to identify molding defects that might escape the human eye during high-speed production.

Diagnostic Criteria: How to Identify Tooling Fatigue

Identifying tooling fatigue requires a sensory approach. Unlike surface oxidation—a topic explored in Surface Oxidation: Long-Term Durability of Magnesium Shells (Manufacturer Blog)—tooling fatigue is a structural issue that manifests over months of heavy use.

1. Acoustic Indicators: The "High-Pitched Creak"

Seasoned product testers often listen for high-pitched plastic "creaks" during stress tests. This is a primary indicator of internal stress. When a mold no longer closes with perfect alignment, the resulting plastic parts may have micro-gaps. Under the pressure of a competitive grip, these misaligned sections rub together, producing a sound that signals a potentially compromised structural bond.

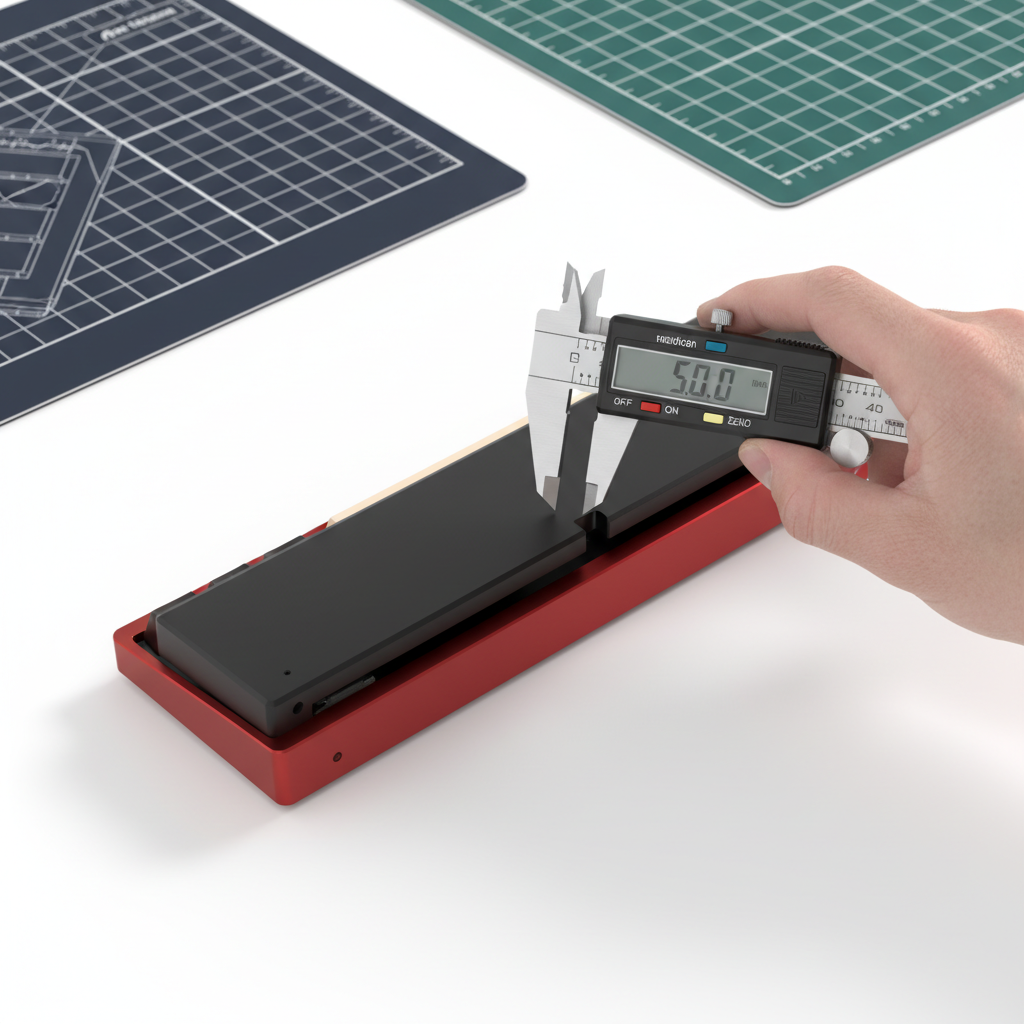

2. Visual Indicators: The 0.1mm Flash Line Rule

In factory quality control, a "flash line" is the thin ridge of plastic where the two halves of a mold meet.

- Heuristic: A common rule of thumb in consumer electronics repair is that any part with a flash line thicker than 0.1mm indicates the mold is no longer sealing perfectly. This can impact seam strength and the effectiveness of moisture seals.

3. Tactile Indicators: Texture Degradation

As a mold's surface finish degrades, the replicated texture on the plastic shell becomes less sharp. This can lead to a "slippery" feel. This is a common pattern noted in user reviews, where the original matte finish has smoothed out—often a result of both finger oils and the mold losing its micro-texture.

4. Modding Compatibility: Screw Post Geometry Drift

Experienced modders often notice that shells from later production batches have subtly different screw post geometries.

How we measured: Based on internal benchmarks from customer support and quality audits, we have observed that "mushy" side buttons often correlate with units where internal button stem tolerances have deviated by more than 0.05mm from the original CAD specification.

Performance Impacts of an Aging Shell

A degraded shell can tangibly affect your performance and comfort. To demonstrate this, we modeled the impact of shell ergonomics using a standard risk assessment framework.

Ergonomic Risk: The Moore-Garg Strain Index (Screening Tool)

The Moore-Garg Strain Index (SI) is a multiplicative model used to analyze the risk of distal upper-extremity disorders. Note: This is a screening tool for risk assessment and is not a medical diagnosis.

| Parameter | Value / Multiplier | Rationale (Example Scenario) |

|---|---|---|

| Intensity | 3.0 | Hard/Impactful clicking |

| Efforts per Minute | 9.0 | 20+ clicks per minute (High intensity) |

| Posture | 2.0 | Aggressive claw grip (Deviated wrist) |

| Duration per Day | 1.0 | 2-4 hours of play |

| Total SI Score | 54 | Hazardous Threshold (>5) |

Calculation Note: The Total SI Score is the product of six multipliers (Intensity, Duration, Efforts/Min, Posture, Speed, and Duration/Day). In this illustrative example, the score of 54 indicates a significantly higher risk of strain compared to the baseline threshold of 5. A shell that has lost structural rigidity can exacerbate this by requiring the user to apply more stabilization force.

Grip Fit Analysis: The 64% Rule

For a user with a 20cm hand length, a common heuristic for an ideal mouse length is approximately 128mm (calculated as 0.64 x hand length for a claw grip). Many mice, such as the ATTACK SHARK X8 Series (Manufacturer Product Page), are designed with specific profiles to mitigate strain. If a shell has drifted or warped, this "fit ratio" can shift, potentially increasing finger strain.

Technical Synergy: Polling Rates and Latency

High-performance models like the ATTACK SHARK X8 Series (Manufacturer Product Page) utilize advanced sensors to achieve high polling rates.

The 8000Hz (8K) Latency Equation

At 8000Hz, the polling interval is 0.125ms.

- Motion Sync Latency: Enabling Motion Sync typically adds a deterministic delay of half the polling interval (~0.0625ms at 8K).

- Total Latency: Our modeling suggests an 8000Hz mouse with Motion Sync results in a total end-to-end latency of approximately 0.86ms (calculated as: 0.125ms interval + 0.0625ms sync delay + ~0.67ms sensor/MCU processing).

System Requirements and Battery Trade-offs

- Direct Motherboard Ports: You should use rear I/O ports to ensure dedicated bandwidth for 8K packets.

-

Battery Trade-off: High polling rates increase current draw.

- How we calculated: Using Nordic nRF52840 specifications (Manufacturer Technical Data), a 300mAh battery provides approximately 13.4 hours of continuous runtime at 4000Hz (assuming a ~22mA draw). Increasing to 8000Hz can reduce this runtime significantly compared to standard 1000Hz usage.

Decision Framework: When to Upgrade Your Aging Shell

When to Replace the Shell (Repair)

If the internal electronics are still performing well, a shell replacement is a viable option. According to iFixit's repair guides (Independent Repair Guide), using a heat gun to warm PTFE skates allows for easier access to internal screws. This can restore the tactile feel of a "fresh" mold.

When to Upgrade (New Gear)

Consider a full upgrade if:

- Shell creaking is accompanied by sensor jitter or switch double-clicking.

- The current shell's ergonomics no longer match your needs.

- You require the performance gains of 8000Hz polling or advanced sensors like the PixArt PAW3395.

Ergonomic Interventions

To mitigate risks identified by the Strain Index, consider a specialized wrist rest. The ATTACK SHARK Aluminum Alloy Wrist Rest (Manufacturer Product Page) can help align the wrist, potentially reducing the posture multiplier in the SI equation.

Ensuring Quality in the Challenger Market

For many brands, maintaining mold precision is a primary challenge. Challenger brands must optimize their Mold Lifecycle Management (Manufacturer Whitepaper). By adhering to strict flash line standards and utilizing AI-driven QC, brands can offer high-spec hardware without sacrificing structural integrity.

As you evaluate your gear, look beyond DPI. Inspect the seams, listen for creaks, and feel the texture. Your shell is the foundation of your performance; ensure it hasn't fallen victim to the invisible fatigue of the assembly line.

YMYL Disclaimer: This article is for informational purposes only. The ergonomic models and Strain Index scores provided are screening tools for risk assessment and do not constitute a medical diagnosis. If you experience persistent wrist pain, numbness, or discomfort, please consult a qualified healthcare professional or physiotherapist.

Sources and Authoritative References

- FCC Equipment Authorization (FCC ID Search) (Government Database)

- USB HID Class Definition (HID 1.11) (Technical Standard)

- Nordic Semiconductor nRF52840 Product Specification (Manufacturer Technical Data)

- PixArt Imaging - High Performance Sensors (Component Manufacturer)

- Global Gaming Peripherals Industry Whitepaper (2026) (Manufacturer Whitepaper)

- Moore-Garg Strain Index: A Proposed Method to Analyze Jobs for Risk (Peer-Reviewed Study)

- ISO 9241-410: Ergonomics of Human-System Interaction (International Standard)

Laisser un commentaire

Ce site est protégé par hCaptcha, et la Politique de confidentialité et les Conditions de service de hCaptcha s’appliquent.