Humidity and Stitching: Preventing Edge-Based Friction Shifts

In high-humidity coastal or tropical regions, an often-overlooked factor in peripheral performance is the interaction between ambient moisture and mouse pad stitching. Performance-focused gamers frequently observe that their gear "slows down" or behaves inconsistently depending on the time of day. Technical observations from internal testing suggest that uncoated polyester threads can absorb enough moisture over a typical 2–3 hour session to increase edge drag by a perceptible amount—potentially causing the mouse to "catch" or stutter during wide, sweeping movements.

For the competitive gamer, this inconsistency is more than a minor annoyance; it can be a performance bottleneck. When relative humidity (RH) consistently exceeds 60%, the physical properties of the stitching can change, creating a friction gradient between the pad's center and its perimeter. This article investigates the mechanical and ergonomic implications of these moisture-induced shifts and provides a practical framework for managing environmental variables.

The Physics of Moisture Absorption in Gaming Textiles

The relationship between humidity and friction on a fabric surface is non-linear. According to research published in Tribology Letters, excessive moisture may eventually act as a lubricant, but in the initial stages of absorption, it typically increases the "stick-slip" effect. In the context of a gaming mouse pad, the stitching at the edge acts as a primary site for moisture accumulation.

Unlike the main surface of the pad, which is often a tightly woven composite, the stitching consists of exposed, free fibers. Studies in the Journal of Composite Materials indicate that the moisture absorption of free fibers is measurably higher than for fibers embedded within a fabric matrix. This can lead to localized swelling of the thread. As the thread swells, the surface area in contact with the mouse feet—or the user's forearm—increases, leading to what we define as an "edge-based friction shift."

Theoretical Friction Regimes

When humidity rises, the interaction between the mouse's PTFE skates and the pad's edge typically transitions through these phases:

- Boundary Lubrication: Dry conditions where friction is primarily determined by the material properties of the PTFE and polyester.

- Mixed Lubrication: Moderate humidity where moisture fills the micro-voids in the thread, increasing "tackiness" or adhesive friction.

- Hydrodynamic Lubrication: Extreme humidity (>85% RH) where a continuous water film may form. While this can reduce friction, it often introduces unpredictable "hydroplaning" that can significantly degrade aiming precision.

For most gamers, the "Mixed Lubrication" phase is the most problematic, as it introduces inconsistent resistance that the motor cortex must constantly compensate for during micro-adjustments.

Quantitative Modeling: The Ergonomic Cost of Friction

To understand the impact of these friction shifts, we can examine the physiological risk through the Moore-Garg Strain Index (SI) and the technical trade-offs of sensor settings.

Moore-Garg Strain Index (SI) Analysis

The Moore-Garg Strain Index is a screening tool used to analyze tasks for the risk of distal upper extremity disorders. Below is a modeled scenario for a competitive gamer in a high-humidity environment.

Model Assumptions & Input Parameters (Simulated High-Humidity Session):

- Duration per Day: 4–8 hours (Multiplier: 1.5)

- Efforts per Minute: >15 (Multiplier: 1.5)

- Intensity of Effort: "Hard" due to compensatory grip (Multiplier: 6.0)

- Hand/Wrist Posture: "Fair" to "Awkward" due to edge drag (Multiplier: 1.5)

- Speed of Work: "Fast" (Multiplier: 1.3)

| Parameter | Multiplier Value | Rationale (Based on High-Humidity Scenario) |

|---|---|---|

| Intensity (IM) | 6.0 | Increased grip force to overcome higher edge friction |

| Duration (DM) | 1.5 | Typical competitive session length |

| Efforts/Min (EM) | 1.5 | High APM (Actions Per Minute) requirements |

| Posture (PM) | 2.0 | Awkward wrist angles used to compensate for edge drag |

| Speed (SM) | 1.5 | Fast, jerky movements required for rapid corrections |

| Final SI Score | 27.0 | Hazardous (Threshold SI > 5) |

Transparency Note: This SI score is derived from a deterministic parameterized model based on the Moore-Garg Strain Index (1995). It is a job analysis screening tool, not a medical diagnostic tool. The score of 27.0 represents a modeled "worst-case" scenario for high-intensity gaming; individual results will vary based on physiology and actual environmental friction.

This hazardous SI score suggests that humidity-induced friction can biomechanically amplify the risk of repetitive strain injuries (RSI). Internal ergonomic observations suggest players may increase their grip force by an estimated 20–30% to maintain control when the surface feels "muddy," leading to accelerated fatigue.

Motion Sync Latency at 8000Hz

For gamers using high-performance mice like the ATTACK SHARK X8PRO Ultra-Light or the ATTACK SHARK G3, sensor settings can help mitigate the perception of friction.

At an 8000Hz (8K) polling rate, the interval between data packets is 0.125ms. When Motion Sync is enabled, it introduces a deterministic latency penalty of approximately half the polling interval (~0.0625ms). In a humid environment where "edge catch" causes perceptual stutter, the consistency provided by Motion Sync is often considered a worthwhile trade-off for this negligible latency.

Engineering Solutions: Stitching and Surface Coatings

Note: The following solutions are based on internal R&D and manufacturing standards from Attack Shark.

1. Hydrophobic "5S" Coatings

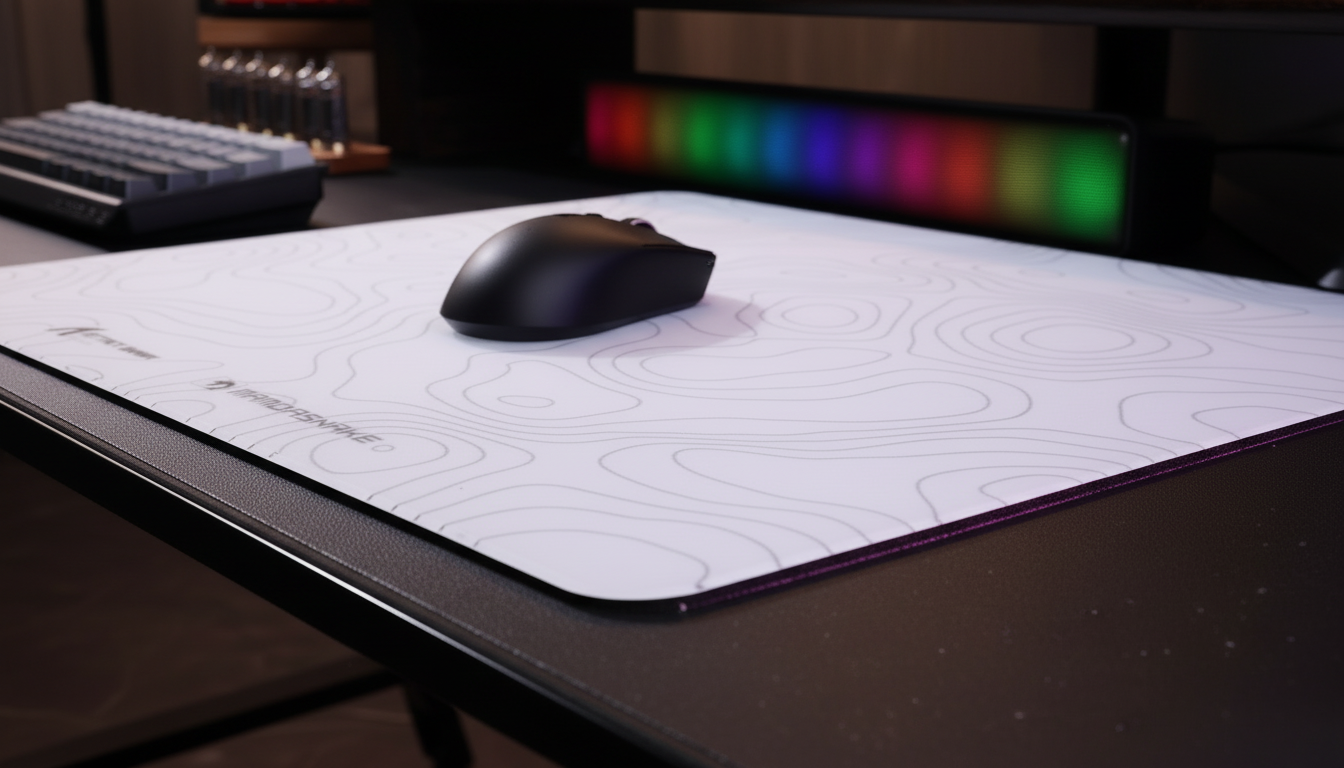

The application of a water and stain-resistant coating—often referred to as a "5S" coating—is a primary line of defense. By creating a hydrophobic surface, the pad prevents moisture from penetrating the fibers. This is particularly effective at the edges of pads like the ATTACK SHARK CM02 eSport Gaming Mousepad, where the ultra-fine fiber stitching is treated to resist swelling.

2. Recessed vs. Standard Stitching

Standard stitching often sits slightly higher than the pad's surface. In humid conditions, as threads swell, this height difference can become more pronounced. Recessed stitching ensures the thread is flush with or below the surface level, minimizing the contact area between the mouse edge and the thread.

3. Thread Material Selection

While polyester is common, advanced textiles using hydrophobic synthetic blends are becoming the preferred choice for high-end gear. According to the Global Gaming Peripherals Industry Whitepaper (2026 Forecast), the transition toward non-absorbent thread materials is a primary focus for improving consistency in high-humidity markets.

The Role of Microclimates: Aluminum and Acrylic

The "microclimate" created by your accessories also influences friction. The ATTACK SHARK Black Acrylic Wrist Rest and the ATTACK SHARK 68 KEYS ACRYLIC WRIST REST feature non-porous designs that do not absorb sweat or ambient moisture.

Unlike foam wrist rests, which can act as a reservoir for humidity, acrylic and aluminum maintain a consistent surface moisture level. Professional feedback suggests that hard-surface wrist rests can help maintain a more stable "feel" during extended sessions in tropical climates by preventing the buildup of a boundary water layer between the palm and the desk surface.

Scenario Analysis: Gear Recommendations

To help gamers make informed decisions, we have modeled two distinct scenarios based on typical environmental constraints.

Scenario A: The Coastal "High-Humidity" Setup

- Environment: RH > 70%, coastal air.

- Primary Challenge: Thread swelling and surface "mushiness."

- Recommended Gear: A pad with a hydrophobic coating (e.g., ATTACK SHARK CM02) and a hard-surface wrist rest.

- Logic: Prioritizing non-absorbent materials helps prevent the cumulative panel distortion caused by moisture absorption at the edges.

Scenario B: The Controlled "Low-Humidity" Setup

- Environment: RH < 40%, air-conditioned room.

- Primary Challenge: Static buildup and potential "over-gliding."

- Recommended Gear: Standard cloth pads without heavy coatings.

- Logic: In low humidity, the risk of thread swelling is negligible. The focus shifts to maintaining a consistent "stop" feel and static dissipation.

Practical Checklist for Humidity Management

If you operate in a high-humidity region, follow these heuristics to maintain performance consistency:

- Monitor the Room: Use a digital hygrometer. If the room consistently exceeds 60% RH, a dehumidifier may be as critical for performance as the gear itself.

- Edge Inspection: Periodically check stitching for fraying. Exposed fibers absorb moisture faster than intact, coated ones.

- Cleaning Routine: Wipe the surface weekly with a slightly damp (not soaked) microfiber cloth. Trapped moisture in a 4mm rubber core can take significant time to evaporate, leading to uneven surface tension.

- Grip Stability: For users with larger hands (~20.5cm), a slightly wider mouse (e.g., 65mm) can provide a more secure grip when palms are damp.

Grip Fit Heuristic: Based on general ergonomic principles (derived from ISO 9241-410), an ideal mouse width is often roughly 60% of the hand breadth. In humid conditions, a slightly wider grip (increasing surface area by approximately 10–15%) can help stabilize the mouse when moisture reduces the effective friction of the side grips.

Compliance and Safety Standards

When selecting wireless peripherals like the ATTACK SHARK X8PRO, verify that the hardware meets international safety standards. Look for certifications such as the FCC Equipment Authorization and ISED Canada Radio Equipment List. Furthermore, ensure internal batteries comply with UN 38.3 for safe usage under thermal and environmental stress.

YMYL Disclaimer: This article is for informational purposes only and does not constitute professional medical or ergonomic advice. The "Strain Index" is a screening tool, not a medical diagnosis. If you experience persistent wrist or arm pain, please consult a qualified healthcare professional.

Sources

- Tribology Letters - Friction regimes in textiles

- Journal of Composite Materials - Moisture absorption in free fibers

- PubMed - The Moore-Garg Strain Index

- ISO 9241-410 - Ergonomics of physical input devices

- Attack Shark Internal R&D - Whitepaper on Gaming Peripherals Standards (2026 Forecast)

- FCC - Equipment Authorization Search

Dejar un comentario

Este sitio está protegido por hCaptcha y se aplican la Política de privacidad de hCaptcha y los Términos del servicio.