The Mechanics of Housing-Induced Rattle

High-frequency rattle and metallic "ping" are among the most persistent frustrations for mechanical keyboard enthusiasts. While many users instinctively reach for lubricants to solve acoustic issues, our observations from the repair bench suggest that a significant portion of these noises originates from physical housing tolerances rather than the internal stem or spring. When the upper and lower housing halves do not snap together with sufficient clamping force, the internal spring can vibrate against the internal walls of the switch, creating a sharp, high-pitched resonance.

This phenomenon is highly material-dependent. In our analysis of various switch compositions, POM (Polyacetal) housings are historically more prone to this issue than newer nylon blends due to POM's lower coefficient of friction and specific vibration characteristics. A common mistake in the DIY community is over-lubricating the stem to dampen this noise. This approach often results in a sluggish, "mushy" keystroke without addressing the root cause: the physical gap between the housing components.

Diagnosing Housing Tolerance Issues

Before initiating a teardown, it is essential to determine if the noise is actually housing-related. A reliable heuristic we use for assessment is the "Lateral Wobble Test."

Rule of Thumb: If lateral wobble on an unmounted switch exceeds 1mm at the top of the keycap, housing tolerance is the likely culprit.

If the housing is loose, the rattle will persist even if the switch is held firmly in place. This indicates that the internal resonance is not caused by the switch moving within the mounting plate, but by the components moving within the switch itself. For enthusiasts using high-performance setups, such as those detailed in the Global Gaming Peripherals Industry Whitepaper (2026), even minor acoustic distractions can break immersion during competitive play.

Advanced DIY Methods for Tightening Housings

Once a housing gap is identified, two primary methods can be employed to increase clamping force and eliminate the high-pitch rattle.

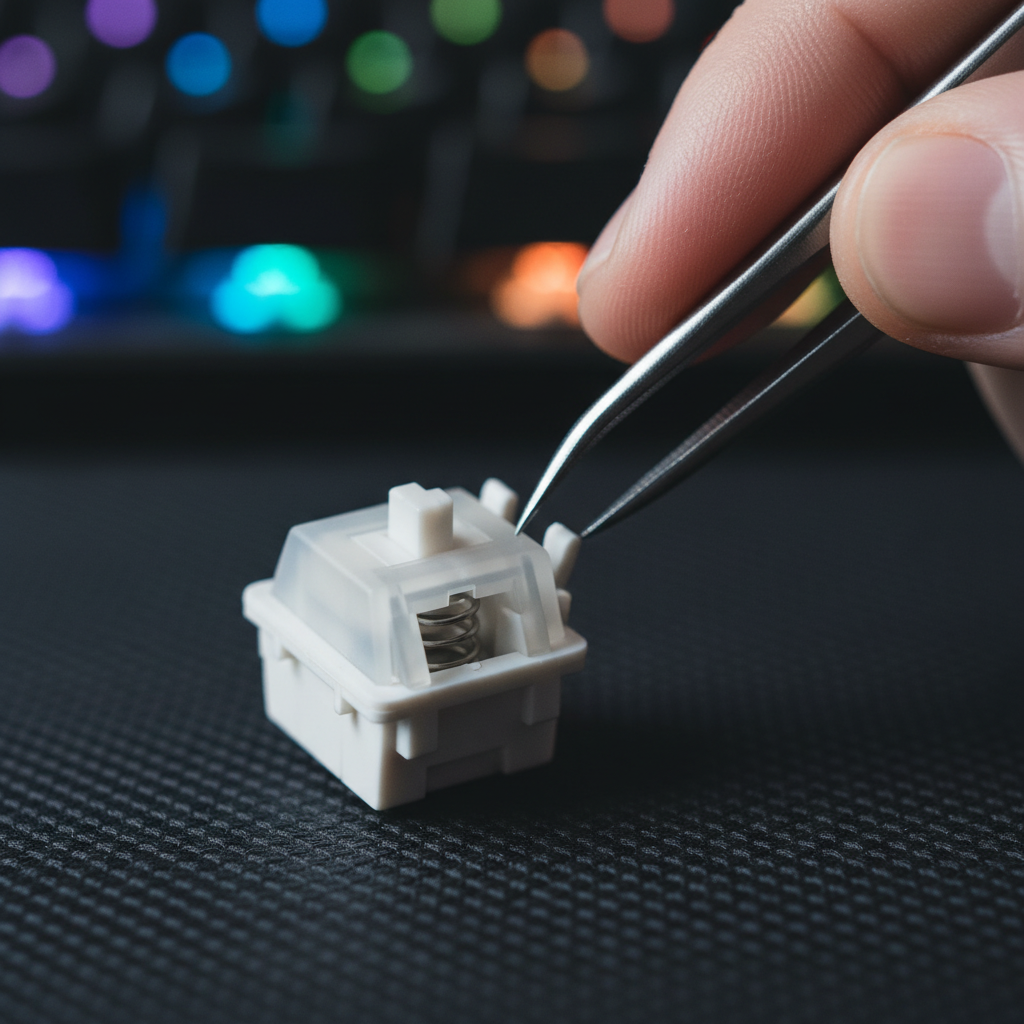

1. Retention Clip Adjustment

Experienced builders often use fine-tipped tweezers to physically modify the retention clips on the lower housing. By carefully bending the four plastic clips inward by approximately 0.5mm before reassembly, you can significantly increase the pressure between the two halves. This mechanical fix addresses the source of the vibration directly.

2. Strategic Use of Switch Films

Applying a 0.15mm-thick switch film (such as those from TX or Deskeys) is a standard procedure for reducing wobble and acoustically dampening housing resonance. However, this method requires caution. According to technical documentation from Same Sky Devices (TS45), industrial switches often operate within a ±0.2mm tolerance range. Adding a film to a switch that already has tight tolerances can over-compress the mechanism, increasing internal friction and degrading the tactile feel.

| Method | Primary Benefit | Potential Risk | Recommended For |

|---|---|---|---|

| Clip Bending | Increases raw clamping force | Risk of snapping plastic clips | Loose POM housings |

| Switch Films | Dampens resonance + reduces gap | Can cause sluggishness if too thick | Polycarbonate/Nylon hybrids |

| POK Stabilizers | Precision-fit stabilization | Hard to DIY; requires replacement | High-end custom builds |

Industrial Standards vs. DIY Heuristics

While the DIY community relies on feel, industrial switch assembly follows strict torque specifications. According to Honeywell's installation guidelines for high-precision switches, proper assembly typically requires a torque of 1.4–1.8 Nm (12–16 in-lb). Exceeding this range by as little as 0.5 Nm can lead to plastic fatigue or premature housing failure.

In the context of 15mm x 15mm mechanical switches, even a "perfect" housing fit may not eliminate all noise if there are PCB integration issues. Resonance can be transmitted through the mounting plate and PCB, meaning that acoustic management must be holistic. For a deeper look at how materials influence these sounds, refer to our guide on Nylon vs. Polycarbonate: How Housing Material Shapes Sound.

Scenario Modeling: The Competitive FPS Player

To understand the impact of keyboard acoustics on gaming performance, we modeled a scenario involving a competitive FPS player with large hands (hand length ~21cm). This user prioritizes sub-millisecond latency and high-frequency auditory cues (like footsteps).

Modeling Note: Motion Sync & System Latency (8000Hz)

For players using high-polling-rate equipment, every microsecond counts. Our model assumes an 8000Hz (8K) polling rate, which equates to a 0.125ms polling interval.

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Polling Rate | 8000 | Hz | High-end esports standard |

| Base Latency | 0.8 | ms | Optimized wireless baseline |

| Motion Sync | Enabled | - | Used for aiming precision |

| Added Latency | ~0.0625 | ms | 0.5 * Polling Interval (0.125ms) |

| Total Latency | ~0.86 | ms | Base + Motion Sync penalty |

Logic Summary: At 8000Hz, the Motion Sync penalty is negligible (~0.06ms). However, high-frequency keyboard rattle in the 2–4kHz range can create auditory masking, making it harder for the player to hear subtle in-game sounds. Tightening housings is not just an aesthetic choice; it is a performance optimization to reduce "auditory clutter."

Acoustic Layering and Component Synergy

Effective rattle elimination often involves more than just the switch housing. The interaction between the switch and the keycap set plays a vital role in the final acoustic profile. For instance, pairing tightened switches with high-density keycaps like the ATTACK SHARK 149 Keys PBT Keycaps Double Shot Full Keycap Set can further dampen high-frequency transients. These 1.5mm thick PBT caps provide a deeper "thock" by acting as a low-pass filter for the sharp clacks produced by the switch housing.

For those prioritizing visual feedback alongside acoustic clarity, the ATTACK SHARK 120 Keys PBT Dye-Sublimation Pudding Keycaps Set offers a translucent lower half that showcases RGB lighting without compromising the structural integrity of the top surface. If you are looking for a quick aesthetic refresh that maintains an ergonomic OEM profile, the ATTACK SHARK Custom OEM Profile PBT Colored Keycaps offer a matte, anti-grease coating that keeps the typing experience consistent even during long sessions.

The Role of Mounting Plates and Foam

If tightening the housings and applying Switch Films does not fully resolve the rattle, the issue may lie in the plate-to-switch interface.

- Plate Tolerance: Some aluminum or steel plates have slightly oversized cutouts. If the switch "clicks" into place but still has lateral movement, consider using a thin layer of gaskets or even the Tempest Tape Mod to bridge the gap.

- Spectral Filtering: Different materials attenuate different frequencies. As shown in our spectral filtering reference, PC (Polycarbonate) plates act as low-pass filters, shifting the fundamental pitch down. Conversely, high-density IXPE switch pads create a "creamy" pop by emphasizing frequencies above 4kHz while dampening the mid-range rattle.

Methodology Note: These acoustic profiles are based on general material physics (Young's Modulus resonance) and common community observations. Perceived sound is subjective and can be influenced by desk material and room acoustics.

Compliance and Global Safety Standards

When performing DIY modifications, it is important to remember that your keyboard is a certified electronic device. High-end peripherals must adhere to global standards to ensure safety and performance. For example, wireless devices are regulated by the FCC Equipment Authorization in the US and the ISED Canada Radio Equipment List in Canada.

Modifications that involve opening the case or altering the PCB can theoretically impact these certifications, particularly regarding RF interference or battery safety. Always ensure that your lithium-ion batteries are handled with care, following IATA Lithium Battery Guidance for transport and safety.

Summary of Best Practices

Eliminating high-pitch rattle requires a methodical approach that moves from diagnosis to mechanical adjustment. By focusing on housing tightness rather than just lubrication, you can achieve a cleaner, more premium sound profile.

- Check Tolerances First: Use the 1mm lateral wobble rule to confirm housing issues.

- Mechanical Over Chemical: Prioritize clip adjustment or filming over excessive lubing.

- Material Awareness: Understand that POM and Polycarbonate will react differently to tightening mods.

- Holistic Build: Complement your switch mods with high-quality PBT keycaps and appropriate plate materials.

For more technical insights on maintaining your gear, explore our guides on How to Lube Mechanical Switches for a Consistent Acoustic Profile and the role of Metal in Hybrid Switch Designs.

Disclaimer: This article is for informational purposes only. DIY modifications to electronic devices may void warranties and carry risks of damage if performed incorrectly. Always consult your manufacturer's guidelines before attempting repairs or modifications. If you are unsure, seek assistance from a professional technician.

コメントを書く

このサイトはhCaptchaによって保護されており、hCaptchaプライバシーポリシーおよび利用規約が適用されます。