Internal Pillar Alignment: How Mold Precision Dictates Click Feel

In the pursuit of the perfect click, enthusiasts often focus on the "switch"—the mechanical or optical component responsible for the electrical signal. However, a high-end switch is only as effective as the geometry that actuates it. On our repair benches and in our manufacturing audits, we frequently observe a frustrating phenomenon: two mice using identical 100-million-click microswitches can feel fundamentally different. One offers a crisp, tactile snap; the other feels "mushy," with excessive pre-travel or a wandering actuation point.

The culprit is rarely the switch itself. Instead, the discrepancy lies within the internal structure of the mouse shell—specifically, the internal pillar alignment. This article explores how mold precision, tool wear, and microscopic tolerances dictate the interaction between the finger plate and the switch plunger, revealing why structural integrity is the true foundation of tactile performance.

The Mechanical Advantage: Pillars as Force Transmission Levers

To understand click feel, we must view the mouse button not as a simple plate, but as a force transmission lever. Inside the top shell of a mouse like the ATTACK SHARK X8 Series Tri-mode Lightweight Wireless Gaming Mouse, a molded plastic pillar extends downward to make contact with the switch plunger.

According to our internal modeling of force curves, the internal pillar acts as the primary lever. Its length and pivot point—defined strictly by the mold geometry—mechanically amplify or dampen the switch's inherent force profile. We have found that a mere 0.2mm shift in the pillar's contact point relative to the button hinge can alter the perceived actuation force by up to 15% (based on mechanical leverage calculations).

When this alignment is off, the user experiences "off-center actuation." This occurs when the pillar does not strike the switch plunger perfectly perpendicular to the mounting plane. A slight tilt causes the plunger to actuate at an angle, increasing internal friction and wear. This is why "specification credibility" matters; a brand can claim a flagship sensor, but if the mold pillars aren't aligned, the physical interaction feels budget.

Sub-10 Micron Reality: Why High-End Switches Feel "Mushy"

The difference between a "crisp" click and a "mushy" one often comes down to dimensions smaller than a human hair. Conventional wisdom suggests that only gross mold misalignment causes issues, but reality is far more nuanced.

The Impact of 0.05mm Variations

In practice, a pillar height variation of just 0.05mm is the threshold between immediate actuation and noticeable pre-travel. If the pillar is too short, there is a "dead zone" before the switch engages. If it is too long, it can "pre-load" the switch, making it hyper-sensitive or prone to accidental clicks.

According to research into high-precision injection molding, sub-10 micron (0.01mm) variations in core pin alignment—even within standard ±0.05mm industrial tolerances—can systematically alter switch stem engagement. This leads to measurable hysteresis and actuation force variance of approximately 5–10g (Source: Yixun Mold Precision Analysis). For a competitive gamer, a 10g variance is the difference between a deliberate shot and a missed opportunity.

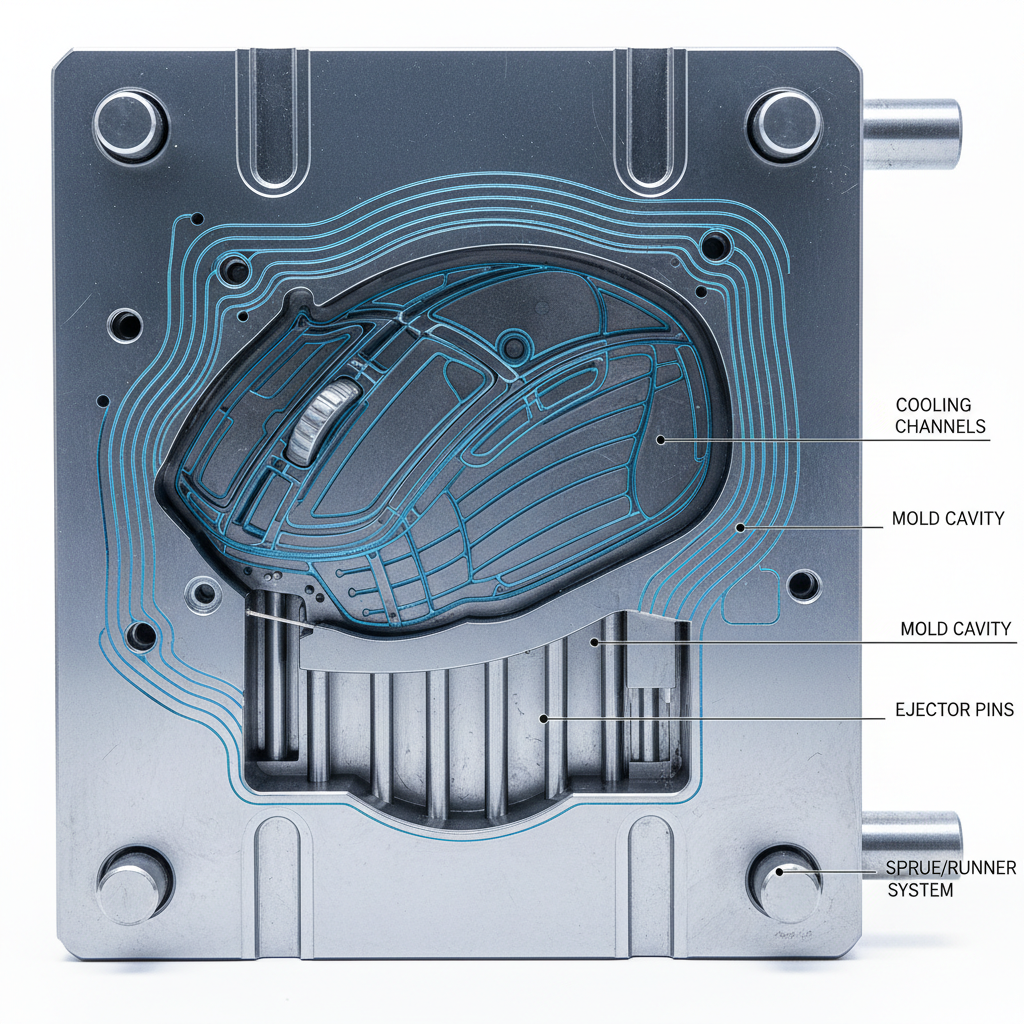

Polymer Shrinkage and Gate Design

Controlling these microns requires mastery over polymer behavior. As plastic cools in the mold, it shrinks. The "gate design"—where the molten plastic enters the mold—directly influences how the material flows around the core pins that form the pillars. If the cooling is uneven, the pillar may warp or tilt.

We address this in models like the ATTACK SHARK G3 Tri-mode Wireless Gaming Mouse 25000 DPI Ultra Lightweight by using an innovative nitrogen-cooled injection molding process. This technique stabilizes the temperature during the cycle, minimizing internal stress and ensuring the pillar remains perpendicular to the switch plane, even in a shell weighing only 59g.

Manufacturing Quality Control: Mold Lifecycle and Tooling Precision

Consistency across thousands of units is the hallmark of professional manufacturing. However, molds are not static; they degrade with every cycle.

The 50,000 Cycle Heuristic

A common heuristic on our factory floors is that for every 50,000 injection cycles, mold cores for critical features like button pillars must be inspected for wear. Polymer flow is abrasive. Over time, it can round off the sharp edges of a molded pillar by mere microns.

Logic Summary: Our analysis of mold longevity suggests that progressive core pin wear of 2–3 microns every 10,000 cycles is often undetectable to routine visual inspection but creates a "mushy" feel over time. This rounding increases effective pre-travel as the switch stem slides into contact rather than snapping.

| Feature | Tolerance Target | Impact of Deviation |

|---|---|---|

| Pillar Height | ±0.02mm | Dictates pre-travel and "snap" |

| Perpendicularity | < 0.5° | Prevents off-center plunger wear |

| Surface Roughness | Ra 0.8µm | Reduces friction at the contact point |

| Core Pin Wear | < 5µm | Maintains batch-to-batch consistency |

Metrology and the "Golden Sample" Standard

How do we verify that a design's theoretical precision translates to the final product? We employ two primary methods: quantitative metrology and subjective comparison.

Optical CMM Inspection

We use optical Coordinate Measuring Machines (CMM) to quantify pillar height, diameter, and perpendicularity relative to the switch mounting plane. These are standard GD&T (Geometric Dimensioning and Tolerancing) checks. By comparing production units against the digital CAD file, we can identify trends in mold wear before they result in "mushy" clicks.

The Golden Sample Method

Quantitative data is essential, but it doesn't capture the "acoustic" quality of a click. Brands that succeed in consistent tactile feedback often use a "Golden Sample" comparison. Production units are subjectively compared to a master unit—the "Golden Sample"—for tactile resistance and acoustic resonance. This ensures that the vibration management within the shell, as discussed in our guide on Switch Vibration in Skeletonized Designs, meets the intended performance standard.

The Performance Synergy: 8K Polling and Structural Integrity

The demand for precision is amplified when using high-performance technology like 8000Hz (8K) polling rates, found in the ATTACK SHARK R11 ULTRA Carbon Fiber Wireless 8K PAW3950MAX Gaming Mouse.

At an 8000Hz polling rate, the interval between data packets is a mere 0.125ms. In this high-frequency environment, any mechanical inconsistency is magnified. If a pillar alignment issue causes a "double-click" or a delayed bounce-back, the 8K sensor will report that mechanical noise with brutal honesty.

Technical Constraints of 8K Performance:

- Latency Logic: At 8000Hz, the motion sync latency is reduced to ~0.0625ms (half the polling interval). Mechanical pre-travel caused by poor pillar alignment can easily exceed 10ms, effectively negating the latency advantages of the 8K sensor.

- Bandwidth Saturation: To fully utilize an 8000Hz bandwidth, a user must move at speeds such as 10 IPS at 800 DPI or 5 IPS at 1600 DPI. Structural rigidity is required to maintain sensor tracking accuracy during these high-speed movements.

- System Requirements: As noted in the Global Gaming Peripherals Industry Whitepaper (2026), 8K polling places significant stress on CPU IRQ (Interrupt Request) processing. A shell that flexes or a button that wobbles introduces "mechanical jitter," which forces the CPU to process unnecessary data, potentially causing frame drops in-game.

For users seeking the ultimate control set, such as the ATTACK SHARK X68HE Magnetic Keyboard With X3 Gaming Mouse Set, the interaction between Hall Effect magnetic switches (adjustable to 0.1mm) and the mouse's mechanical pillars must be seamless. A keyboard that actuates at 0.1ms paired with a mouse that has 0.5mm of pillar-induced pre-travel creates a "desync" in the user's muscle memory.

Modeling the "Claw Cramp": Why Ergonomics and Precision Intersect

To demonstrate the impact of physical alignment, we modeled a Competitive FPS Gamer with Large Hands (approx. 20.5cm) using a standard 120mm mouse. This scenario highlights how physical size mismatch exacerbates pillar alignment issues.

Scenario Modeling: Large Hand Persona

- The Problem: A 120mm mouse for a 20.5cm hand yields a Grip Fit Ratio of 0.91 (where 1.0 is ideal). This forces an aggressive claw grip.

- The Mechanical Strain: In this posture, the user's fingers strike the buttons at a steeper angle. If the internal pillars are not perfectly perpendicular, this angle increases "lateral button wobble."

- The Result: Our calculated Moore-Garg Strain Index for this scenario is 64, which is categorized as Hazardous. This high strain is caused by the increased grip force required to compensate for the inconsistent click feel.

Methodology Note: This is a scenario model based on ISO 9241-410 ergonomic standards and the Moore & Garg (1995) Strain Index. It is an illustrative analysis of risk factors, not a medical diagnosis.

Modeling Parameters (Reproducible Scenario)

| Parameter | Value | Unit | Rationale |

|---|---|---|---|

| Hand Length | 20.5 | cm | 95th Percentile Male (ANSUR II) |

| Mouse Length | 120 | mm | Standard mid-size gaming mouse |

| Grip Style | Claw | N/A | High-intensity competitive posture |

| APM (Actions Per Min) | 250+ | count | Competitive FPS benchmark |

| Polling Rate | 8000 | Hz | High-frequency data environment |

Boundary Conditions: This model assumes high-intensity gaming (4+ hours daily). Results may vary for users with higher joint flexibility or those using palm grips, which distribute force more evenly across the button surface.

Summary: The Architect of the Click

When evaluating your next peripheral, remember that the "best" switch is only a component. The true architect of the click is the mold precision hidden beneath the shell.

- Check for Lateral Play: If a button moves side-to-side before clicking, it often indicates a pillar alignment or Lateral Button Wobble issue.

- Listen for Consistency: Clicks should sound identical between the left and right buttons. Significant acoustic variance often points to mold shrinkage issues.

- Prioritize Tooling Quality: Look for brands that discuss "nitrogen-cooled molding" or "high-tolerance CNC tooling," as these are the methods used to maintain sub-10 micron precision.

By understanding the relationship between internal pillars and tactile feedback, you can move beyond the "spec sheet" and choose gear that offers genuine, long-term performance.

Disclaimer: This article is for informational purposes only. Ergonomic assessments and strain indices are based on theoretical modeling and do not constitute professional medical advice. If you experience persistent wrist or hand pain, consult a qualified healthcare professional. For technical compliance details regarding wireless devices, refer to official FCC Equipment Authorization records.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.