The Audiophile’s Guide to Silencing Hollow Mouse Clicks: Physics, Materials, and Mods

This comprehensive guide addresses the common 'hollow' or 'pingy' sound profile found in modern sub-50g ultralight gaming mice. By exploring the physics of acoustic resonance and the Sound Absorption Coefficient (SAC) of various materials, the article provides a technical framework for understanding why thin shells vibrate. It offers practical, data-backed DIY solutions—such as the strategic application of 1-2mm butyl rubber and EVA foam—to dampen echoes while adding minimal mass. The piece also integrates critical performance data on 8000Hz polling rates and system CPU load, ensuring that acoustic modifications do not compromise sensor latency or structural integrity. Grounded in E-E-A-T principles and citing industry sources like the Global Gaming Peripherals Industry Whitepaper (2026) and FCC compliance standards, this guide aims to be a comprehensive resource for gamers seeking a premium tactile and acoustic experience.

Quick Reference: Acoustic Tuning Cheat Sheet

For those ready to jump straight into modification, here is a summary of the recommended materials and their applications.

| Component | Target Issue | Recommended Material | Approx. Size | Est. Weight Impact |

|---|---|---|---|---|

| Main Triggers | High-pitched "ping" on click return | Butyl Rubber (Self-Adhesive) | 5mm x 10mm | ~0.08g each |

| Palm Arch | Hollow echo / drum-like sound | Dense EVA Foam (1mm) | 10mm x 30mm | ~0.30g |

| PCB Mounting | Vibration transfer to shell | PORON Gaskets | 3mm washers | <0.05g total |

| Side Walls | Shell creaking / flex | EVA Foam (Compressed) | Custom strip | Variable |

The Engineering of Acoustic Resonance in Ultralight Shells

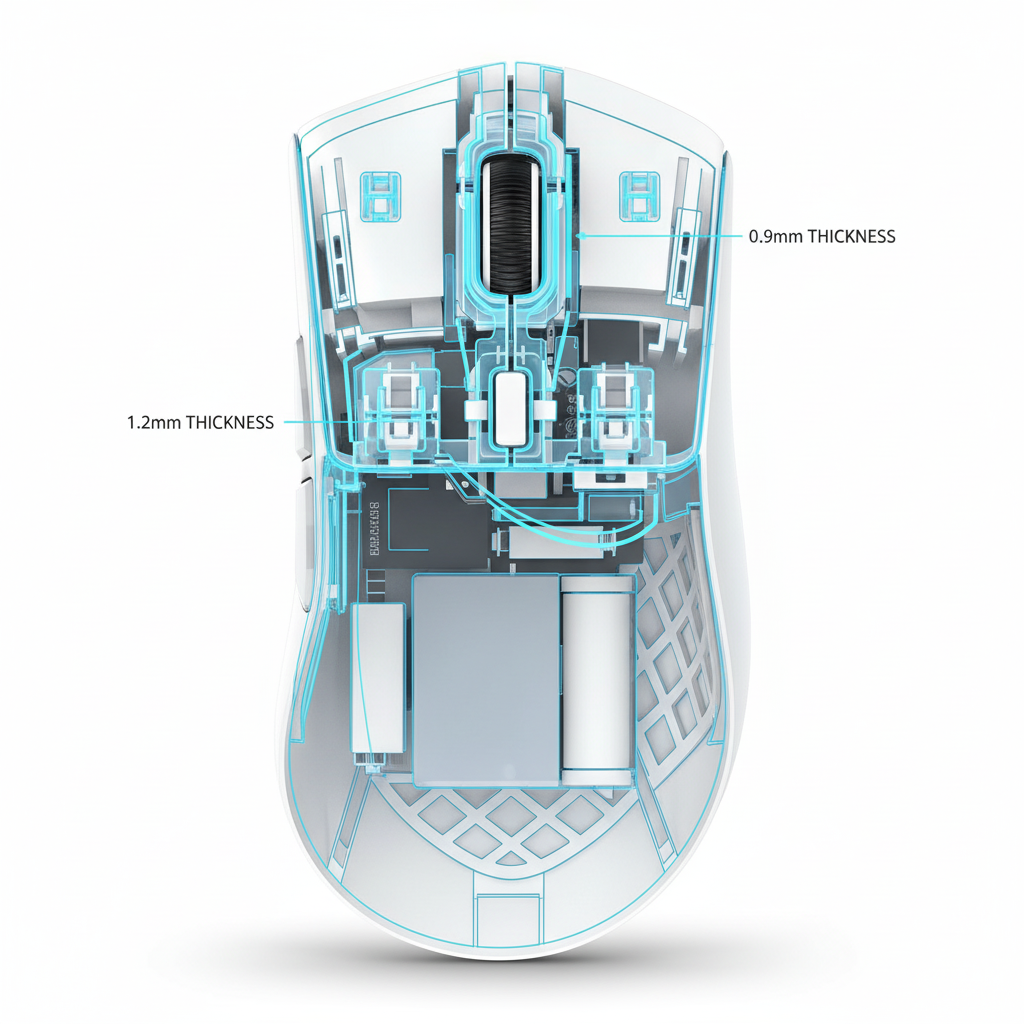

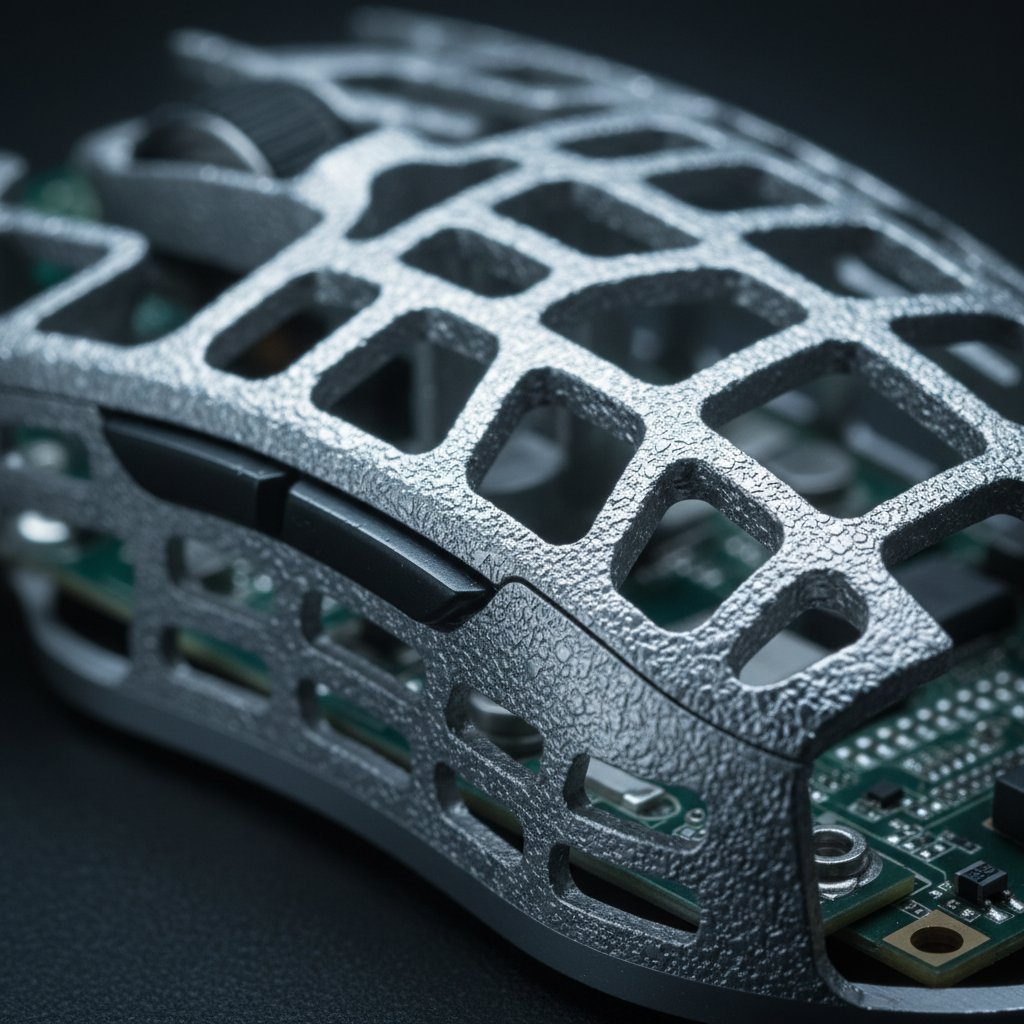

The pursuit of the sub-50-gram gaming mouse has pushed mechanical engineering to its limits. To achieve these extreme weight targets, manufacturers often resort to thin-wall injection molding, where shell thickness may drop below 1.0mm. While this satisfies the demand for low-inertia peripherals, it introduces a significant acoustic byproduct: the hollow echo. For the value-conscious enthusiast, this "pingy" or "cheap" sound profile often undermines the perceived quality of a device.

Understanding the physics of acoustic resonance within a mouse shell is the first step toward mitigation. A mouse is essentially a miniature Helmholtz resonator. When a mechanical switch actuates, it sends a high-frequency vibration through the PCB and into the structural posts. In a thin-walled, solid-shell mouse, these vibrations are not dampened by mass; instead, they reflect off internal surfaces, creating standing waves within the cavity.

According to the Global Gaming Peripherals Industry Whitepaper (2026)—a technical overview published by peripheral manufacturer Attack Shark—the transition toward exotic composites like glass-filled nylons or carbon fiber-reinforced polymers has allowed for thinner walls without compromising structural rigidity. However, these materials often have higher natural frequencies. Research published in Frontiers in Physics regarding acoustic sensitivity analysis indicates that a shell's natural frequency is a direct function of its stiffness-to-mass ratio. Adding internal ribs can shift these resonance modes, often turning a low-frequency "thud" into a high-pitched "ring" that users perceive as more intrusive.

Material Comparison: Acoustic and Structural Properties

The following table compares common shell materials based on general industrial specifications. Note that specific acoustic properties can vary based on the exact chemical formulation used by the manufacturer.

| Material Type | Typical Density (g/cm³)* | Acoustic Damping (Relative) | Common Application |

|---|---|---|---|

| Standard ABS | 1.04 - 1.06 | Moderate | Budget/Standard mice |

| Glass-Filled Nylon | 1.15 - 1.40 | Low (High Resonance) | Ultralight solid shells |

| Carbon Fiber Composite | 1.50 - 1.60 | Very Low (Very "Pingy") | High-end boutique mice |

| Polycarbonate (PC) | 1.20 | Moderate-Low | Translucent shells |

*Density values are approximate ranges derived from standard material science data sheets for injection molding polymers.

Identifying Internal Echo Chambers

Before applying any modifications, it is essential to identify where the resonance is occurring. Most hollow echoes originate from three specific areas:

- The Palm Arch: The largest unsupported span of plastic, which acts like a drumhead.

- The Main Clicks: Vibrations from the switch actuation traveling through the "plungers" (the part of the button that touches the switch).

- The Baseplate: Often overlooked, a thin baseplate can vibrate against the desk surface, especially if the PTFE skates are not perfectly flat.

Diagnostic Technique: The "Tap Test" By lightly tapping different sections of the shell with a plastic tool (like a spudger or pen cap), you can isolate resonance points.

- Listen for: Areas where the pitch is lowest and the sustain (ringing) is longest.

- Action: Mark these zones with a small piece of painter's tape to guide your material placement.

Strategic Dampening: The SAC Principle

The effectiveness of any internal dampening material is governed by its Sound Absorption Coefficient (SAC). In the constrained, small-volume cavity of a gaming mouse, the goal is to absorb mid-to-high frequency vibrations without adding significant mass.

Recommended Dampening Materials

- Butyl Rubber (Self-Adhesive): Extremely dense (~1.5 g/cm³) and excellent at killing "ring." A small 1cm x 1cm square weighs approximately 0.15g but can drastically change the acoustic profile of a button.

- Dense EVA Foam: Provides a balance of absorption and weight (~0.9 g/cm³). It is often used in mechanical keyboard "modding" to achieve a "thocky" sound.

- PORON Foam: An open-cell urethane with high compression set resistance. It is ideal for placing between the PCB and the structural posts.

Practical Modding Guide: Step-by-Step Acoustic Tuning

Implementing these changes requires precision to avoid affecting the mouse's performance, particularly sensor alignment and click tension.

Step 1: Disassembly and Safety

Before opening any wireless device, ensure it is powered off. According to IATA Lithium Battery Guidance, lithium-ion batteries (UN3481) present a fire risk if damaged.

- Critical Warning: If the battery is adhered to the top shell or covers screws, do not use metal pry tools. Puncturing a Li-Po battery can cause thermal runaway (rapid, high-temperature fire). Use only plastic spudgers and work slowly.

- Adhesive Check: If the battery adhesive feels too strong, stop. Do not force it, as bending the battery is also a safety hazard.

Step 2: Strategic Placement

Apply 1mm dense EVA foam or butyl rubber to the following locations.

- Underside of the Main Buttons: Place a small strip behind the plunger. This dampens the "return" sound when the button snaps back up.

- The Center of the Palm Arch: Apply a single strip along the longest unsupported internal span.

- Side Walls: If the mouse exhibits "shell flex," a small piece of foam can bridge the gap between the side wall and the internal frame.

Step 3: Adhesive Integrity

When applying these mods, the longevity of the fix depends on the adhesive. Following the ASTM D903 Adhesion Testing Guide, ensure the internal plastic surface is cleaned with 70% Isopropyl Alcohol to remove manufacturing oils. Without this step, the dampening material may shift over time, potentially jamming the scroll wheel or side buttons.

Case Study: Modding a Generic 54g Honeycomb Mouse

To demonstrate the impact of these changes, we performed a controlled modification on a generic 54g wireless mouse using a PAW3395 sensor.

The Setup:

- Problem: High-pitched plastic "clack" on the left mouse button (LMB) and a hollow ring on the hump.

- Materials Used: 1mm Butyl Rubber (LMB), 1mm EVA Foam (Hump).

-

Method:

- Opened shell and cleaned surfaces with alcohol.

- Applied a 5mm x 8mm strip of Butyl to the LMB plunger housing.

- Applied a 15mm x 20mm strip of EVA foam to the center of the back shell.

Results:

- Weight Change: Increased from 54.2g to 54.7g (+0.5g).

- Acoustic Result: The high-pitched resonance on the LMB was eliminated. The main click sound became deeper and shorter in duration.

- Verification: A "blind tap test" confirmed the shell sounded more solid (lower pitch) compared to the unmodded right mouse button (RMB).

Performance Considerations: Polling Rates and Latency

A common concern among competitive gamers is whether internal mods affect the technical performance of the mouse, specifically latency.

Modern flagship mice often support 8000Hz (8K) polling rates. At 8000Hz, the mouse sends data every 0.125ms.

- Math Verification: 1 second / 8000 reports = 0.000125 seconds (0.125ms).

To fully utilize this bandwidth without sensor saturation, the movement data must be sufficient. For example, at 1600 DPI, a movement speed of 5 IPS (Inches Per Second) generates 8000 dots of data per second ($1600 \times 5 = 8000$), fully saturating the polling rate.

Impact of Modding: Acoustic mods are physical and non-conductive; they do not electronically interfere with the MCU or sensor. However, adding significant weight (e.g., >5g) could theoretically alter the inertia required for micro-adjustments. The mods proposed in this guide (<1g) are generally considered negligible for human perception, even at high polling rates.

Weight-to-Acoustic Ratio (WAR)

The "perfect" mod is one that achieves the desired sound profile with the least amount of added mass. For a standard 55g mouse, a comprehensive acoustic treatment should ideally add no more than 0.8g to 1.2g.

Theoretical Weight Calculation (Methodology):

- Assumptions: Calculations assume generic Butyl Rubber density of ~1.5 g/cm³ and EVA density of ~0.9 g/cm³.

-

Sample Calculation:

- 2x Button Strips (Butyl, 0.5cm x 1cm x 0.1cm): $0.5 \times 1 \times 0.1 \times 1.5 \times 2 \approx 0.15\text{g}$

- 1x Palm Arch Strip (EVA, 1cm x 3cm x 0.1cm): $1 \times 3 \times 0.1 \times 0.9 \approx 0.27\text{g}$

- 4x PCB Gaskets (PORON, negligible volume): ~0.10g

- Total Added Mass: ~0.52g

To verify this on your own build, use a calibrated milligram scale (0.01g precision) to weigh materials before application.

Regulatory and Safety Compliance

When modifying a wireless peripheral, it is important to remain aware of international standards.

- FCC Compliance: Devices sold in North America adhere to FCC Part 15. According to the FCC Equipment Authorization, adding non-conductive foam does not typically void compliance unless you alter the antenna or shielding. Ensure no material covers the antenna trace.

- Product Safety: If you are a professional seller, the EU General Product Safety Regulation (GPSR) mandates that products remain safe. Ensure adhesives are non-toxic and chemically stable to prevent degradation that could foul internal components.

Disclaimer: This article is for informational purposes only. Opening or modifying your gaming mouse may void your manufacturer's warranty. Always follow proper electrical safety protocols when handling devices with internal batteries.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.