The Technical Science of Anodized Aluminum Maintenance

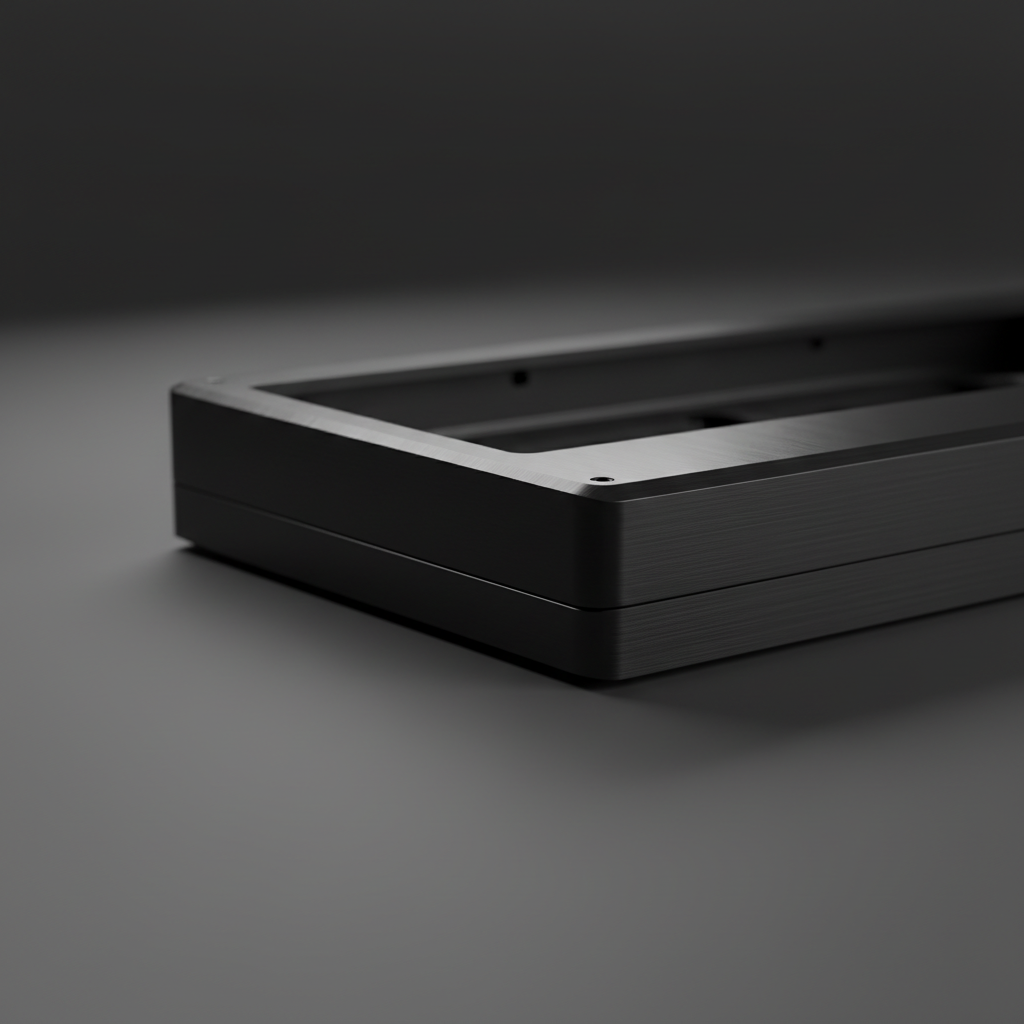

Premium mechanical keyboards often utilize 6061 or 7075-grade aluminum alloys, finished through an electrochemical process known as anodization. This process converts the metal surface into a decorative, durable, and corrosion-resistant anodic oxide finish. Unlike paint or plating, anodization is integrated with the underlying aluminum substrate, making it exceptionally stable. However, this layer is typically only 5 to 25 microns thick (Source: Hard Anodizing Aluminum: Thickness, Hardness, Design Guide).

For the tech-savvy enthusiast, understanding the vulnerability of this micron-thin layer is critical. While the oxide layer is technically harder than the base metal, it is also more brittle and porous. Improper cleaning techniques—such as using abrasive materials or harsh chemicals—can wear through the colored layer to the bare aluminum underneath. Once this occurs, the damage is irreversible. This guide outlines a technically precise maintenance routine designed to preserve the tactile quality and aesthetic integrity of high-end metal peripherals.

Material Vulnerabilities and Common Pitfalls

Maintaining a metal keyboard requires a departure from generic electronics cleaning advice. Many common household items act as micro-abrasives that degrade the surface finish over time.

The "Sandblasting" Effect of Compressed Air

A common misconception is that compressed air is a universally safe first step for debris removal. In reality, forceful, direct blasts can turn loose particles into micro-projectiles. According to industrial application data regarding compressed air usage, high-pressure streams can scour surfaces. For an anodized keyboard, this mimics low-grade sandblasting, which can dull the sheen or create localized pitting if the nozzle is held too close.

Abrasive Fibers: Microfiber vs. Paper Towels

The choice of wiping material is paramount. Even "soft" paper towels often contain wood fibers or fillers that act like fine sandpaper on anodized coatings under pressure (Source: Microfiber Cloths vs. Paper Towels).

- Microfiber Principle: High-quality microfiber cloths (split-fiber) are designed to lift and trap particles within the weave rather than dragging them across the surface.

- The Contamination Trap: A critical mistake is reusing a microfiber cloth that has picked up abrasive dust from previous sessions. Practitioners note that a "dirty" cloth can cause more damage than no cleaning at all.

Optimized Chemical Selection and Dilution Ratios

The chemistry of cleaning agents interacts directly with the sealed pores of the anodic oxide layer. Using the wrong concentration can lead to "pore degradation," resulting in a loss of luster or increased susceptibility to staining.

The Problem with Soap and 99% IPA

While mild soap is often recommended, it frequently leaves a hydrophilic residue. This film attracts atmospheric dust and skin oils, creating a cleaning cycle that necessitates more frequent wiping, thereby increasing long-term micro-scratching.

Furthermore, while 70-99% isopropyl alcohol (IPA) is excellent for sanitizing, high concentrations can degrade the sealants used in the anodization process. According to research on alcohol safety for aluminum, high-purity alcohol may lead to a loss of sheen over time.

The Recommended Solution: 30-50% Diluted IPA

For stubborn grime, a 50/50 mix of distilled water and 99% IPA is highly effective. Distilled water is essential because tap water contains minerals (calcium, magnesium) that can leave white "water spots" or contribute to galvanic corrosion in the presence of electrical currents (Source: The Behavior of Metals in Distilled Water vs Tap Water).

| Cleaning Agent | Recommended Concentration | Risk Level | Primary Impact |

|---|---|---|---|

| Distilled Water | 100% | Low | General dust removal; no residue. |

| Isopropyl Alcohol | 30% - 50% | Moderate | Effective grease removal; safe for seals. |

| Mild Dish Soap | < 1% (Diluted) | Moderate | Leaves hydrophilic film; attracts oils. |

| 99% Isopropyl Alcohol | Undiluted | High | Potential pore sealant degradation. |

| Ammonia-based Cleaners | Avoid | Critical | Chemical etching of the oxide layer. |

Methodology Note: These concentration limits are based on common industry heuristics for maintaining decorative anodic finishes (Scenario Modeling: Decorative vs. Hard Anodizing).

Step-by-Step Maintenance Protocol

To avoid micro-abrasions, the mechanical motion of cleaning must be as controlled as the chemical application.

- Debris Extraction: Use a soft-bristled brush (such as a clean makeup brush or a dedicated anti-static keyboard brush) to gently sweep away loose particles. If using compressed air, maintain a distance of at least 6 inches and use short, angled bursts.

- Initial Wipe: Dampen (do not soak) a fresh microfiber cloth with distilled water. Wipe the surface using straight, linear motions. Avoid circular scrubbing, which can create visible swirl marks under direct light.

- Targeted Degreasing: For areas with heavy oil buildup (e.g., around the spacebar or volume knob), use the 30-50% IPA solution. Apply the solution to the cloth first, never directly to the keyboard.

- Moisture Management: Moisture ingress is a significant risk for mechanical keyboards, especially those with lithium-ion batteries. According to US DOT PHMSA lithium battery guidelines, liquid contact can lead to internal shorts or corrosion.

- The 24-Hour Rule: After any damp cleaning, remove the keycaps and allow the board to air-dry in a warm, low-humidity environment for 24 to 48 hours before reconnection. This ensures any trapped moisture evaporates from the switch plate and PCB (Source: iFixit Mechanical Keyboard Cleaning Technique).

Advanced Scenario Analysis: The Competitive Esports Professional

For high-performance gamers, maintenance isn't just about aesthetics—it's about preserving the functional integrity of the device. We modeled a scenario involving a competitive professional to understand how cleaning impacts performance and ergonomics.

Ergonomic Strain and Maintenance

Competitive gaming involves high Intensity, Duration, and APM (Actions Per Minute). Using the Moore-Garg Strain Index—a tool adopted by organizations like OSHA—we calculated the strain for a professional gamer.

Modeling Note (Reproducible Parameters):

- Intensity Multiplier: 2.0 (High actuation force)

- Duration Multiplier: 1.5 (4-6 hour sessions)

- Efforts Per Minute: 4.0 (300-400 APM)

- Posture Multiplier: 2.0 (Aggressive claw grip)

- Speed Multiplier: 2.0 (Rapid keypresses)

- Result: SI = 96 (Hazardous Category)

This high strain index (SI=96) highlights that any cleaning routine requiring excessive force or awkward wrist extension could exacerbate existing repetitive strain risks. Maintenance should be quick and require minimal physical exertion to avoid adding to the user's cumulative trauma.

Acoustic Profile Preservation

Enthusiasts often prize the "thock" sound profile of premium metal keyboards. This profile is achieved through specific spectral filtering provided by internal damping layers like Poron foam or IXPE pads.

- Thock (< 500 Hz): Deep, muted sound.

- Clack (> 2000 Hz): Sharp, high-frequency sound.

Improper cleaning that allows liquid to seep into these damping layers can alter their viscoelastic properties. For example, if moisture saturates a Poron case foam, it may lose its ability to attenuate mid-high (1-2kHz) frequencies, shifting the keyboard's acoustic signature from a deep "thock" to a harsh, metallic "clack."

Performance Synergy: 8000Hz and System Latency

Maintaining a clean surface also ensures that physical obstructions do not interfere with high-performance features like 8000Hz (8K) polling rates. In the world of competitive gaming, every microsecond counts.

The Math of 8K Polling

A keyboard operating at 8000Hz has a polling interval of 0.125ms (1000ms / 8000). To achieve the temporal consistency required for this speed, the system must be free of bottlenecks.

- Motion Sync Latency: On high-end gear, Motion Sync aligns sensor framing with the USB Start of Frame. At 8000Hz, this adds a negligible deterministic delay of approximately ~0.0625ms (0.5 * 0.125ms).

- System Requirements: To visually perceive the smoothness of an 8K polling rate, a high-refresh-rate monitor (240Hz+) is typically required. Furthermore, 8K polling places significant stress on the CPU's IRQ (Interrupt Request) processing.

According to the Global Gaming Peripherals Industry Whitepaper (2026), users should connect 8K devices directly to the motherboard's rear I/O ports. Using USB hubs or front-panel headers can cause packet loss and signal degradation, negating the benefits of the high polling rate.

Long-Term Preservation Strategies

Beyond regular cleaning, environmental control is the most effective way to protect anodized aluminum.

- Dust Covers: Utilizing a clear acrylic dust cover when the keyboard is not in use significantly reduces the accumulation of abrasive particles and skin oils.

- Humidity Control: Aluminum is naturally corrosion-resistant due to its oxide layer, but high humidity can accelerate the degradation of internal components. Maintaining a room humidity level between 40% and 60% is generally considered optimal for both the user and the hardware.

- Handling Hygiene: Washing hands before use is the simplest way to reduce the transfer of acidic skin oils (sebum) which, over years of use, can subtly etch even the toughest anodized finishes.

Summary Checklist for Safe Cleaning

- Use: Fresh microfiber cloths, distilled water, 30-50% diluted IPA.

- Motion: Linear, straight-line wipes only.

- Avoid: Paper towels, 100% IPA, ammonia, high-pressure air, circular scrubbing.

- Safety: 24-hour air-dry period after damp cleaning.

Disclaimer: This article is for informational purposes only. Maintenance of electronic devices involves inherent risks, including electrical shock or permanent hardware damage. Always disconnect power sources before cleaning. If you are unsure about a specific cleaning agent, test it on a small, inconspicuous area of the keyboard case first. For ergonomic concerns, please consult a qualified healthcare professional.

References

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.